تخفيض السعر!

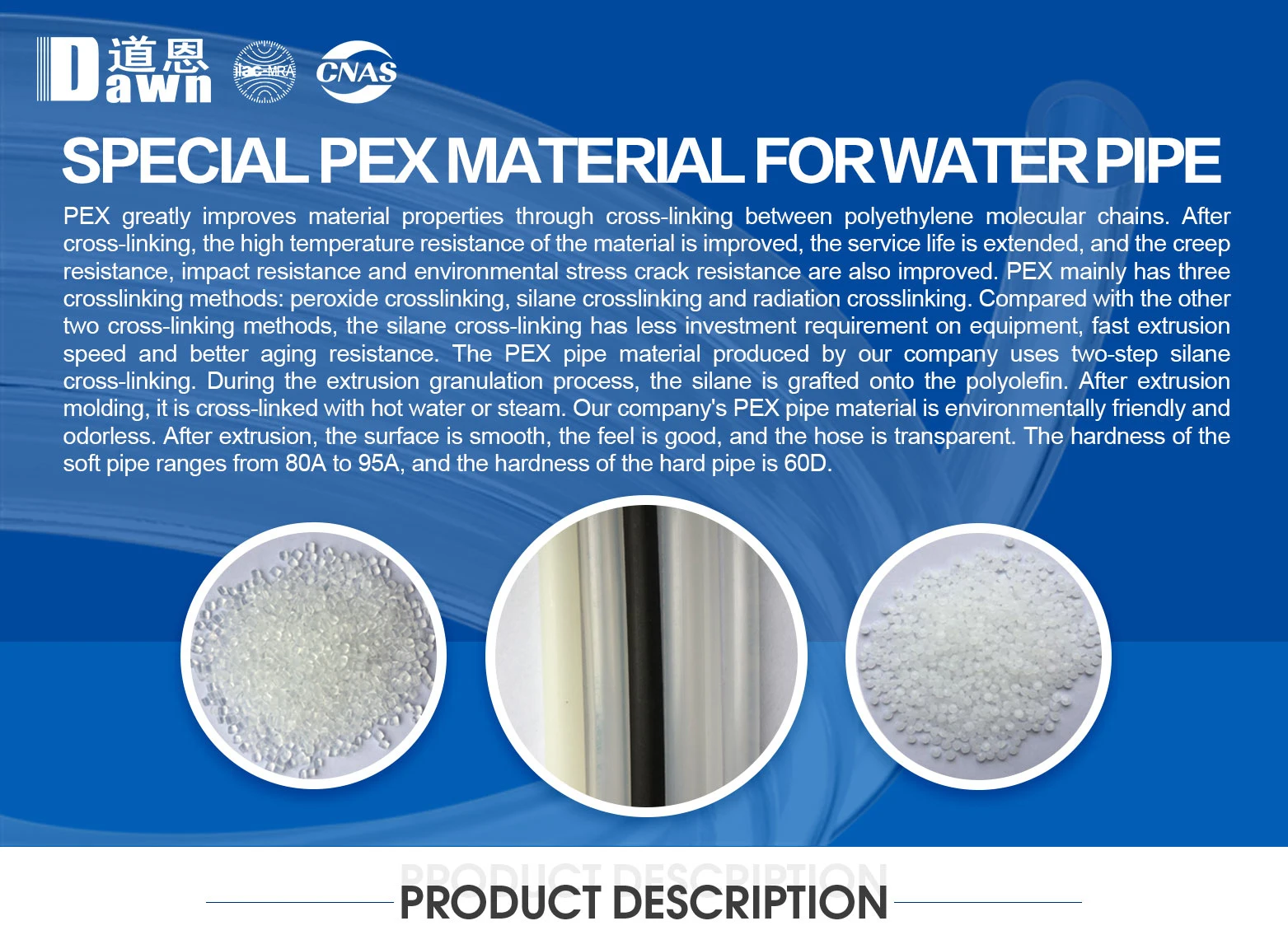

Special PEX Material for Water Pipe

وصف

وصف المنتج

تخصيص

مشروع | Test Method | Unit | PEX-CDN6D | PEX-CDN9 | PEX-CDN8 |

كثافة | GB/T1033 | g/cm3 | 0.94±0.01 | 0.91±0.01 | 0.89±0.01 |

قوة الشد | GB/T1040 | MPa | ≥18 | ≥18 | ≥12 |

Elongation at break | GB/T1040 | % | ≥400 | ≥500 | ≥500 |

Shore hardness | GB/T2411 | - | 60±2D | 95±2A | 87±2A |

Vicat softening Temp | GB/T1633 | ℃ | ≥120 | ≥90 | ≥75 |

Crosslinking degree | GB/T18474 | % | ≥65 | ≥65 | ≥65 |

ملف الشركة

التعبئة & توصيل

التعليمات

1.Why is the surface of the silane crosslinking PEX extruded pipe not smooth and there are bumps of different sizes sometimes?

2.Will the normal use be affected because of a small amount of cosmid and long grains in the material?

3.Why do the materials of the same grade have different soft touch hardness when they are extruded at different times?

After the silane crosslinking PEX pipe material is wetted, local cross-linking will occur to form gel particles, and bumps of various sizes will be formed on the surface of the pipe during extrusion molding. This material needs to be kept dry during packaging, وسائل النقل, storage and unpacking. Damage to the outer packaging and long storage time after opening will cause moisture to the material.

2.Will the normal use be affected because of a small amount of cosmid and long grains in the material?

In the process of material production, cosmid and long grains sometimes occur. A small amount of cosmid and long grains will not affect the feeding of extruder and the normal use of materials.

3.Why do the materials of the same grade have different soft touch hardness when they are extruded at different times?

The hardness of the same grade material is stable while the diameter & wall thickness of pipes and ambient temperature willaffect the soft touch hardness.