Rebaja!

Top selling Wiped Film Molecular Distillation Equipment, ship from US

Descripción

Descripción de productos

Training and installation support

Fast delivery from California warehouse and Shanghai factory

contact for more surprises and discount right now!

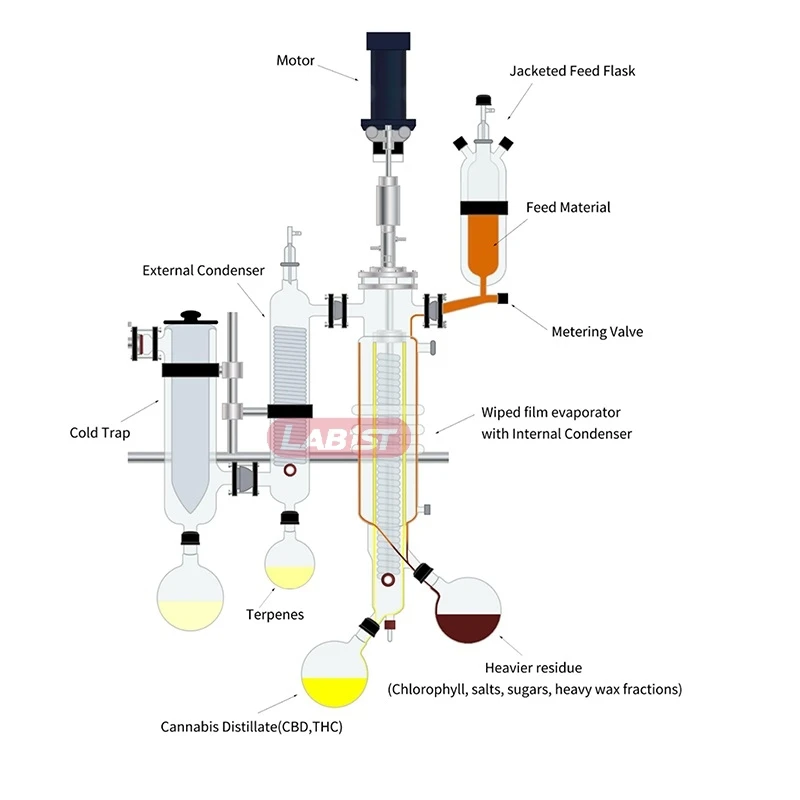

LAB1ST wiped film molecular distillation unit is superior than traditional short path distillation kit by shorter residence time, lower separation temperature, capability of continuous and unattended operation. The units are available in various sizes (from 100mm diameter to 300mm or more), with processing speed up to 40kg/h.

Glass Wiped Film Distillation Unit

Características: Clear to observe, cost-effective choice

Tallas: 1.15sqft, 2.7sqft, 3.8sqft effective evaporation area // Throughput: 1-7kg/h

Fully Upgraded Glass Wiped Film Distillation Unit – TYPE C

* Continuous Feeding with peristaltic pump

* Continuous Discharging with isolate flask

* Dewar style cold trap + stainless steel coil with extra chiller, dual usage

* Better vacuum environment with rotary vane vacuum pump + diffusion pump

* Supporting chillers and heaters

* All accessories

* Continuous Discharging with isolate flask

* Dewar style cold trap + stainless steel coil with extra chiller, dual usage

* Better vacuum environment with rotary vane vacuum pump + diffusion pump

* Supporting chillers and heaters

* All accessories

Hybrid Wiped Film Distillation Unit

Características: Clear to observe, dual in use

Tallas: 2.7sqft, 3.8sqft effective evaporation area // Throughput: 3-7kg/h

Hybrid Wiped Film Distillation Unit – TYPE B

* Continuous Feeding with peristaltic pump

* Continuous Discharging with isolate flask

* Dewar style stainless steel cold trap +

stainless steel coil with extra chiller, dual usage

* Better vacuum environment with rotary vane vacuum pump + diffusion pump

* Supporting chillers and heaters

* All accessories

* Better vacuum environment with rotary vane vacuum pump + diffusion pump

* Supporting chillers and heaters

* All accessories

Fully Upgraded Hybrid Wiped Film Distillation Unit – TYPE C

* Continuous Feeding with Gear Pumps

* Continuous Discharging with Gear Pumps

* Continuous Discharging with Gear Pumps

* Fully Jacketed Pipeline

* Dewar style cold trap + stainless steel cooling coil equipped with a -80℃ chiller, dual usage

* Better vacuum environment with rotary vane vacuum pump + diffusion pump

* Supporting chillers and heaters

* All accessories

* Better vacuum environment with rotary vane vacuum pump + diffusion pump

* Supporting chillers and heaters

* All accessories

Stainless Steel Wiped Film Distillation Unit

Características:Faster distillation rate , durable in use

Tallas: 1.1sqft, 3.2sqft, 5.4sqft effective evaporation area // Throughput: 7-50kg/h

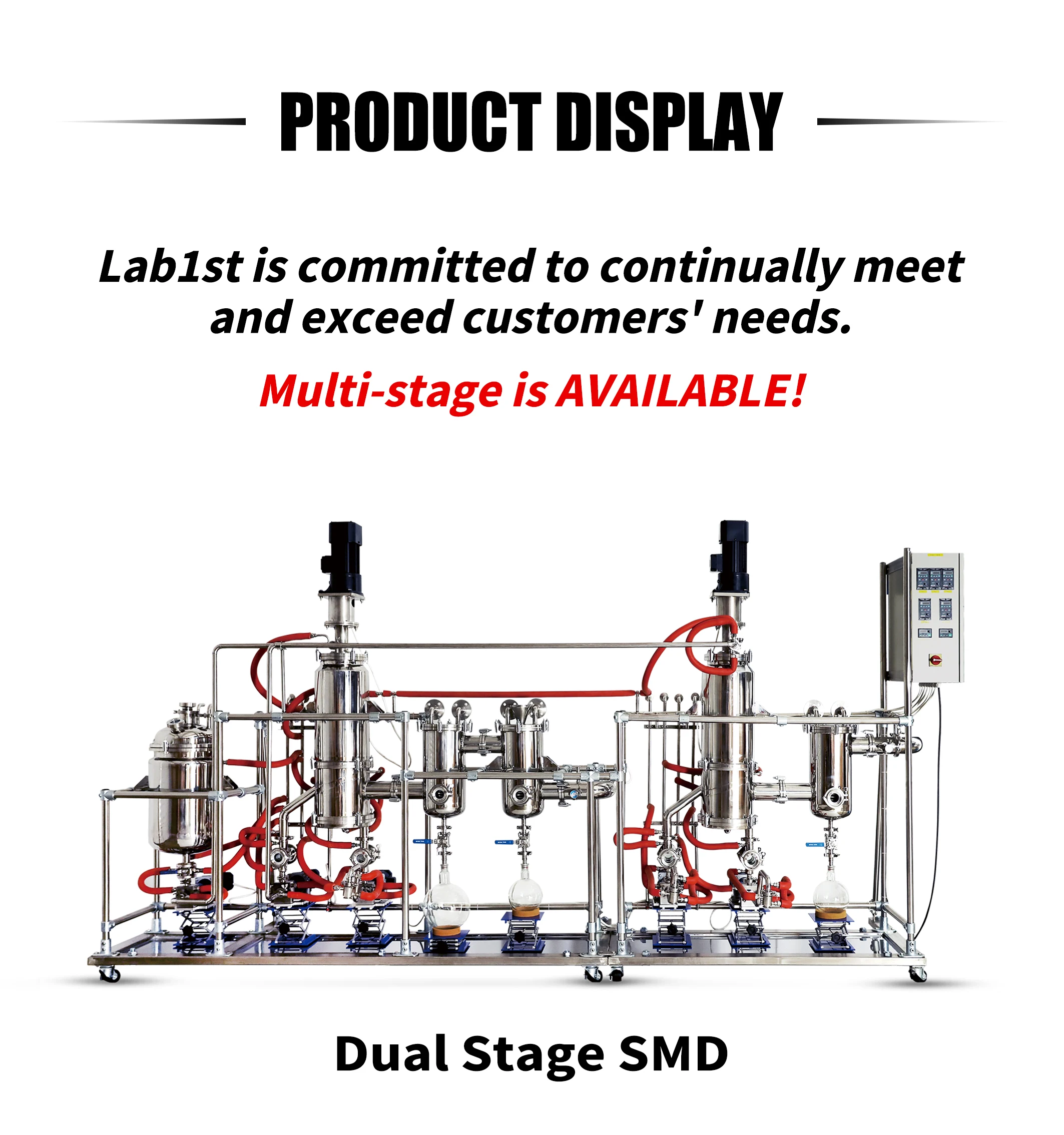

For Dual stage machine:

* Use first stage to remove terpenes, and use second stage to make distillation, a increase efficiency

* Or Use both stages to make distillation, to get higher purity oil

Para 3 stages machine:

* Use first stage to remove solvent, like ethanol; Use the other two stages to remove terpenes and make distillation

Productos relacionados

Clients Cases

Sobre nosotros

Contáctenos

Información Adicional

| Lugar de origen: | Porcelana |

|---|---|

| Nombre de la marca: | Lab1st |

| Condición: | Nuevo |

| Escribe: | Distillation |

| Inspección saliente de video: | Previsto |

| Informe de prueba de maquinaria: | Previsto |

| Tipo de comercialización: | Producto ordinario |

| Garantía de los componentes principales: | 1 Año |

| Componentes principales: | SOCIEDAD ANÓNIMA, Motor, Recipiente a presión, Bomba |

| Solicitud: | Distillation |

| Peso (KG): | 560 KG |

| Garantía: | 1 Año |

| Servicio posventa proporcionado: | repuestos gratis, Instalación de campo, puesta en marcha y formación, Servicio de mantenimiento y reparación en campo., Soporte técnico de vídeo, Soporte en línea |

| Puntos de venta clave: | Precio competitivo |

| Después del servicio de garantía: | Soporte técnico de vídeo, Soporte en línea |

| Industrias aplicables: | Distillation |

| Ubicación del servicio local: | Estados Unidos |

| Ubicación de la sala de exposición: | Estados Unidos |

| Dimensión(L*A*A): | 7 cartones |

| Material: | Borosilicate 3.3 Vidrio |

| Temperatura de funcionamiento: | Up to 250℃ |

| Función: | Distillation |

| Certificado: | CE , YO ASI |

| Vacuum Pump: | Pirani Style |

| Stirrer Seal: | Oil-less Magnetic |

| Wiper: | PTFE Scraper |

| Maximum Speed (rpm): | 350 |

| Recycle receiving flask: | 3L |

| Distillate receiving flask: | 5L |