Best Price Insulated copper battery bus bar with pvc Cover

La description

Best Price Insulated copper battery bus bar with pvc Cover

RHI is an industry leader in fabricated copper bus bars and aluminum bus bar systems including a complete line of high current secondary AC and DC custom aluminum bus bars used for new energy systems and battery pack applications.

We provide precision milled assemblies to high volume punched and stamped components. Our advanced CNC, CAM and Solid Works technologies enable us to maintain tight control over quality to fit our customers’ exact specifications or to OEM specifications.

All copper bus bar manufacturing activities meet ISO 9001 and TS/IATF16949 standards.

| Material Standard | GB : T2 Copper with Min. 99.9% DEPUIS: E-Cu58 (Number: 2.0065) DANS: Cu-ETP ( Number: CW004A) ISO: Cu-ETP UNS: C11000 JIS: C1100 Bs: C101 Other Material also can be customized |

| Résistance | 0.00001Oh |

| Conductivity | 57% |

| Copper busbar thickness | 1mm-10mm depend on bus bar structure, we will advise suitable thickness |

| Insulation Material | PVC Dipping Coating performs well for special shaped bus bar,which can be put on directly. It is not easy to break when it be bent with many times. |

| Flame Retardant/Fire Resistance | UL94-V-0 or upon you request |

| Leakage Testing | PVC Dipping Sleeves: In condition of 3500VDC with 30s upon thickness 1.5mm, Leakage is 0.025 MA; In condition of 5000 VAC with 30s to 60s upon thickness 1.8mm to 2.0mm, Leakage is 0.065 MA; Or upon your working voltage, we advise to choose better solution. |

| Surface Plating | Nickel, tin or silver plated etc Plating Thickness:Normalement 3um to 12um or upon customers’ request |

| Salt Spray Testing | In a neutral environment, nickel can bear 240 heures. Silver is lower, tin is lowest |

| Bending Testing | Bend 10000 times in 15 radian angle without breakage or fracture. |

| Temperature Rise Testing | Depend on flexible busbar cross-sectional area, We can offer all temperature rising test report before delivery if you request |

| Température de fonctionnement | -45 à +150 ºC |

| Copper busbar Tensile Strength | ≥500N |

| Quote Time | Quotation sheet will be sent in 1-3 working days when receive your enqiury |

| Sample/Trial Order Heure de livraison | Dans 5 -15 working days according to different bus bar structure and manufacture process |

| Quality Management Standard | Meet Auto Industry IATF 16949 |

| Eco-friendly Certificate | RSST, ATTEINDRE |

|  |  |

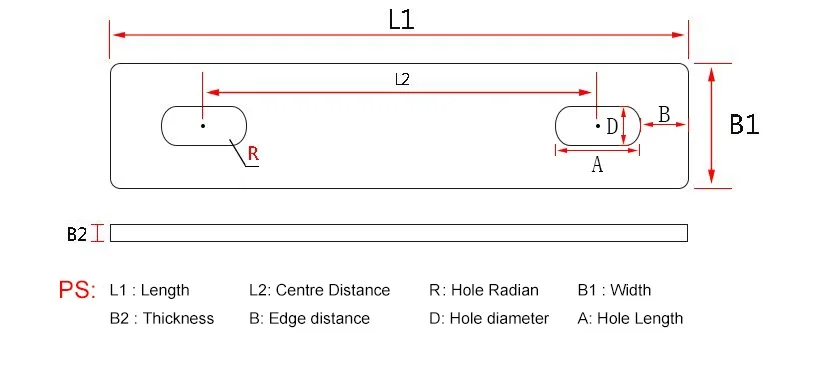

Dimension

New energy vehicle; Battery packs; Power supply room; Power distribution equipments;

Switchboards;Panel boards; Low and medium voltage switchgear;

Low voltage distribution; High current & control equipment; Busway systems etc

Testing Capabilities

| Test Programs | Tester | Standard | Test Result |

| Endurance test | Endurance meter | upon your request | √ |

| Release force test | Universal material testing machine | upon your request | √ |

| Loop resistance,contact resistance test | Loop resistance testing equipment | upon your request | √ |

| Temperature rising test | Temperature rising tester | GB/T14048.1-2000 | √ |

| Electric conductivity test | Conductivity tester | YS/T478-2005 | √ |

| Salt spray test | Salt spraying tester | GB/T2423.17-2008 | √ |

| Thermal ageing, heat vibration test | Air exchange aging test machine | upon your request | √ |

| Coating thickness test | X-ray coating thickness tester | upon your request | √ |

| Voltage drop test | Voltage drop tester | upon your request | √ |

1.Perfect management systems: Implement ISO9001 & IATF16949 and provide PPAP document.

2.Professional sales team:plus que 6 year export experience and 24-hour service line to meet customer’s need.

3.Premium quality:test from raw material to packaging and many advanced testing equipments,like temperature tester,electrical conductivity tester.

4.High production efficiency and low cost :10 year experience of production and complete production chain.

5.Highly intelligent production workshop: robot production line and high-precision machines.

Informations Complémentaires

| Lieu d'origine: | Zhejiang |

|---|---|

| Marque: | RHI |

| Numéro de modèle: | busbar |

| Couleur: | Nickel or tin plated ( le noir, orange, rouge ) |

| Article: | battery bus bar |

| Copper Content: | 99.9% |

| Taille: | various |

| Placage: | tin plating |

| Thickness of plating: | 3-5 μm |

| Insulated coating: | 2:1 heat shrink tube |

| Goûter: | available |

| FEO: | ok |

| Application: | battery conducting |

| Visiting company: | accueillir |