Vente!

Self color anodizing metal hand crafted cremation urns for ashes

La description

Description du produit

spécification

Matériel | AL1070 1.3mm |

Traitement de surface | Brushed |

Spinning surface available | brushed, polished, peinture, powder coating, anodizing, Zinc plating |

Spinning material available | aluminium, copper, brass and stainless steel, carbon steel, |

Spinning thickness available | 0.5-4millimètre |

Certificat | ISO 9001:2015 ,RoHS |

Processus de production

Metal spinning is a forming process that produces hollow parts that are typically circular in cross-section. The basic metal

spinning process starts with a flat metal disc (blank), which rotates on a lathe. This rotating blank is pressed against a tool

(chuck mandrel) that duplicates the interior of the part.

Historically metal spinning was associated with prototypes and low volume production time. However, with the introduction of automatic and CNC lathes metal spinning is now a cost-effective option for both medium and high volume production. The relatively inexpensive tooling price still makes this forming method a cost effective one for fabricating prototypes.

spinning process starts with a flat metal disc (blank), which rotates on a lathe. This rotating blank is pressed against a tool

(chuck mandrel) that duplicates the interior of the part.

Historically metal spinning was associated with prototypes and low volume production time. However, with the introduction of automatic and CNC lathes metal spinning is now a cost-effective option for both medium and high volume production. The relatively inexpensive tooling price still makes this forming method a cost effective one for fabricating prototypes.

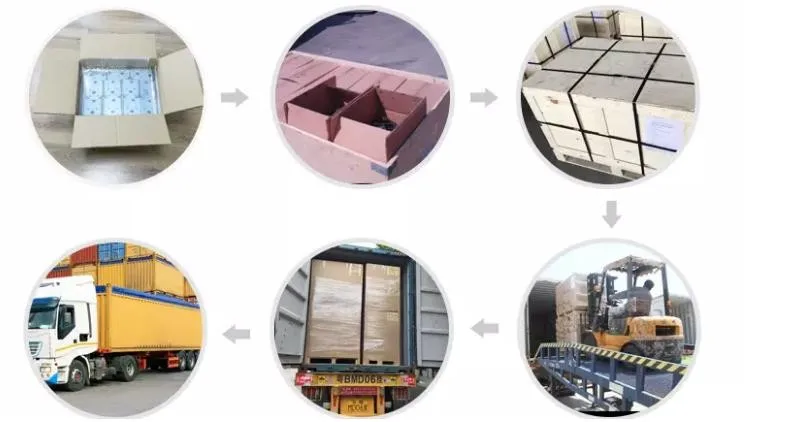

Emballage & Livraison

As the most of the spinning goods are used for decoration, so they have high requirement on the surface. Wotech will packed each part with PE Foam to avoid any damage. To save the shipping cost, Wotech will find a best way by CAD for container shipping. We care what you care.

Profil de l'entreprise

FAQ

Certificats

As an ISO 9001 certified company cooperating with ISO and TS certified suppliers, our customers are all relying on us to deliver first class quality products. We are familiar with standard operating procedure for all customers incorporates the automotive PPAP (Production Part Approval Process) quality system for part qualification.Our in-house quality department technicians make sure that every lot of parts to ensure it meets our customers’ highest standards and expectations.

Our Engineering services includes: Conceptual design, Rapid Prototyping, FIMA, APQP, part production with PPAP, 3D model analysis, independent warehouse QC and QA and a traceable product data management to meet AQL requirement.

All our operations are strictly compliant with ISO 9001: 2008 guidelines and VDA five quality management tools.

Our Engineering services includes: Conceptual design, Rapid Prototyping, FIMA, APQP, part production with PPAP, 3D model analysis, independent warehouse QC and QA and a traceable product data management to meet AQL requirement.

All our operations are strictly compliant with ISO 9001: 2008 guidelines and VDA five quality management tools.

Informations Complémentaires

| Lieu d'origine: | Shangai, Chine |

|---|---|

| Marque: | Wotech |

| Numéro de modèle: | FEO |

| Taper: | Urn |

| Matériel: | métal, Aluminium |

| Style: | European style |

| Application: | ANIMAUX |

| Nom du produit: | Brass anodizing metal hand crafted cremation urns for ashes |

| Traiter: | Spinning |

| Traitement de surface: | Self color anodizing |

| Certificat: | ISO 9001:2015 |

| Volume: | 90 cubic inches |

| Skype: | wotech-amanda |