Descrizione del prodotto

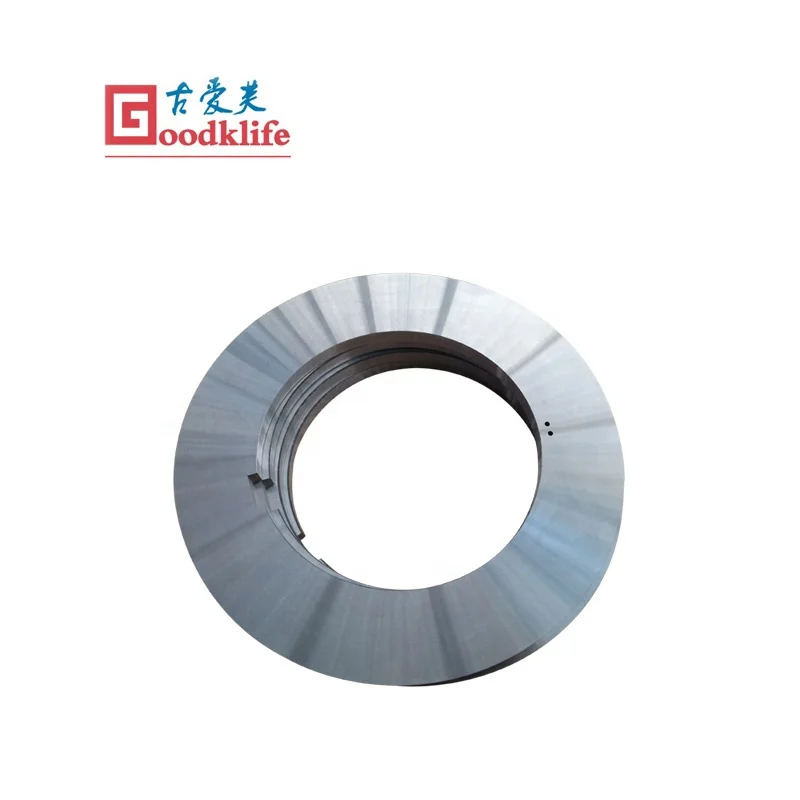

Circular knife for slitter cutter

Materiale | High alloy tool steel, like H13, H13K, D2, SKD11, LD, 6CrW2Si etc. |

Durezza | According to the application |

Applicazione | Slitting line, side trimmer line |

Merits | Goodklife patent raw material, with longer work life |

Dimensione | Personalizzato |

Servizio | Regrinding, on-site checking( clearance and overlap, machine run out), eccetera. |

Introduzione dell'azienda

Goodklife Machinery Technology Co., Ltd Ma’anshan is located in Bowang Town which is one of the most famous town for blades in China, Goodklife has more than 30 years experience in this line. The company has been committed to providing knives and blades of high productivity and high precision. From raw material, heat treatment to finishing, Goodklife keeps track and exercises strict control over every piece, in order to improve the performance of our products and production efficiency, at the same time reduce the production cost.

Goodklife is specializing in shearing blades, slitting knives, fly shear blades, scrap shear blade and other industrial blades.

The products are widely used in steel industry, metallurgical industry and so on. Goodklife can produce shear blade with max length 5500mm and circular knives with max OD 1500mm, the knives can be made by qualified alloy tool steels, include 6CrW2Si, Cr12MoV, H13, D2, SKD11, SKD61 AND also Goodklife’s independent developed raw materials, G1, G2 and G3. These materials are excellent for high tensile strength, high hardness, high toughness and high hardenability. Accroding to most clients’ feedback, our G1 and G2 ensure much longer worklife, about 1.8 time and 1.4 time longer.

Production Progress

Steel-making

Goodklife company can meet special requirements for materials. In order to guarantee the quality, the company imported the spectrometer from Germany and is equipped with various testers, such as tensile tester, impact testing machine, metallography analyzer and so on.

Electro Slag Remelting

The ESR remelted material improve following mechanical characteristics :

1. Improved toughness due to increased homogeneity and isotropy

2. Improved creep resistance properties

3. Best fatigue strength and tenacity properties as well as outstanding tensile strength

4. Improved purity

Forging Steel

The largest electro-hydraulic hammer is 4.5 ton. And more than 6 skilled technicians work for us. After forging, the inside microstructure becomes much closer and the metal grain size becomes much smaller. It can evevate the characteristics and quality of the knife ensuring a longer life.

Rough Processing

No less than 40 sets of processing equipment in the rough processing workshop of Goodklife company, including lathe ,milling machine, planer, drill machine etc. Skilled workers are employed in its rough processing workshop.

Heat Treatment

Goodklife company has independent workshop for heat treatment. Couples of skilled technicians work here. Actually all blades can be fully hardened. Thus, the blades can be used after repairing until the size reached the minimum design dimension.

Precision Grinding

Goodklife company has more than 35 sets of processing equipment including internal grinder, external grinder, surface grinder, CNC grinder, electric spark CNC wire-cut etc. The company can produce the shearing blades with 5500mm in length and slitting knives with 1500mm in outside diameter.

Lapping

Goodklife can process the knives surface with lapping or polishing according to clients’ requisiti. The thickness tolerance, parallelism, flatness, surface quality could be very high precision.

Final Inspection

Various testers are put to use for testing its products in Goodklife company. They are including tensile tester, impact testing machine, metallography analyzer, harmless flaw detector, magnetic powder inspection, tester di durezza, caliper rule, microcalliper etc. Testing is carried out after each step. And every product has a unique track number. Thus it is easy to trace back anytime .

prodotti correlati

Imballaggio&Spedizione

Inside packing: Applied with anti-rust oil and then packed in plastic bag

Outside packing: Packed in strong plywood case(NO NEED FUMIGATION)

Perché scegliere noi

Individual design of tooling system

With Goodklife Tool Design Questionnaire, accurate quantity Knives, Rubber Bonded Rings, Spacers and other tools will be recommended. Every cent makes sense, avoiding wasting and excessive investment.

Solutions for special slitter-tooling, designed for your applications.Technical service from our engineers to assist you in solve the problem of cutting edge and realizing a higher quality output. Like regrinding advice, clearance and overlap adjusting, machine run out checking etc.

On-site Inspection

If needed, our teem will visit the client and check the precision condition of machine. Relevant advises will be provided and help the clients to improve cutting performance together.

Seminar and Training

In order to improve the cutting experience, relevant seminar and training are available and will be held at our customers’ site.