XPS sandwich board for wall insulation

Description

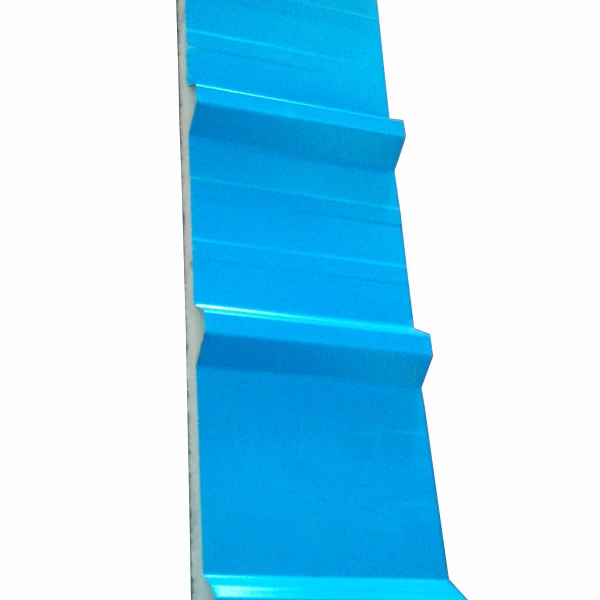

Color steel sandwich panel is made of extruded polystyrene (XPS) foam board or expandable polystyrene (EPS) foam board with two sides galvanized steel plate covered.

The surface can be made one side flat, other side corrugated for roofing or both sides flat for wall.

It is now widely used in largespan factory, purification plant, villas, office buildings, refrigeration project, cold store, clean room, truck body etc..

Item | Face Board | Core | Back Board |

Material | steel | XPS/EPS board | steel |

Thickness (mm) | 0.3-0.6 | 30-100/50-200(optional) | 0.3-0.6 |

Standard Width (mm) | 1000, 1200 | 1000, 1200 | 1000, 1200 |

Effective Width (mm) | 950, 1150 | 950, 1150 | 950, 1150 |

Standard Length(mm) | 2400,2440, 2950, 5900 | 2400,2440, 2950, 5900 | 2400,2440, 2950, 5900 |

Customized dimensions are available if required.

Characteristics:

1. Water-resistant

2. Excellent Thermal Insulation :Low thermal conductivity ensures excellent insulation property

3. Dimensional Stable

4. Light weight makes convenient for transportation and handling duct work

5. Resistant to deformation

6. Easy installation, save cost, save space

7. Long Service Life

8. Anti-microbial Corrosion, Anti-chemical corrosion, Anti-aging

9. Green environmental protection, energy-saving, non-toxicity,CFC and bromine free

Additional information

| Warranty: | More than 5 years |

|---|---|

| After-sale Service: | Online technical support |

| Project Solution Capability: | Others |

| Application: | Workshop |

| Design Style: | Contemporary |

| Place of Origin: | Zhejiang, China |

| Brand Name: | Shield |

| Model Number: | XPS |

| Panel Material: | metal |

| Apparent Density: | 35-40 |

| Heat Conductivity: | 0.029-0.036W/M.K |

| Highest Working Temperature: | 75 |

| Material: | Polystyrene |