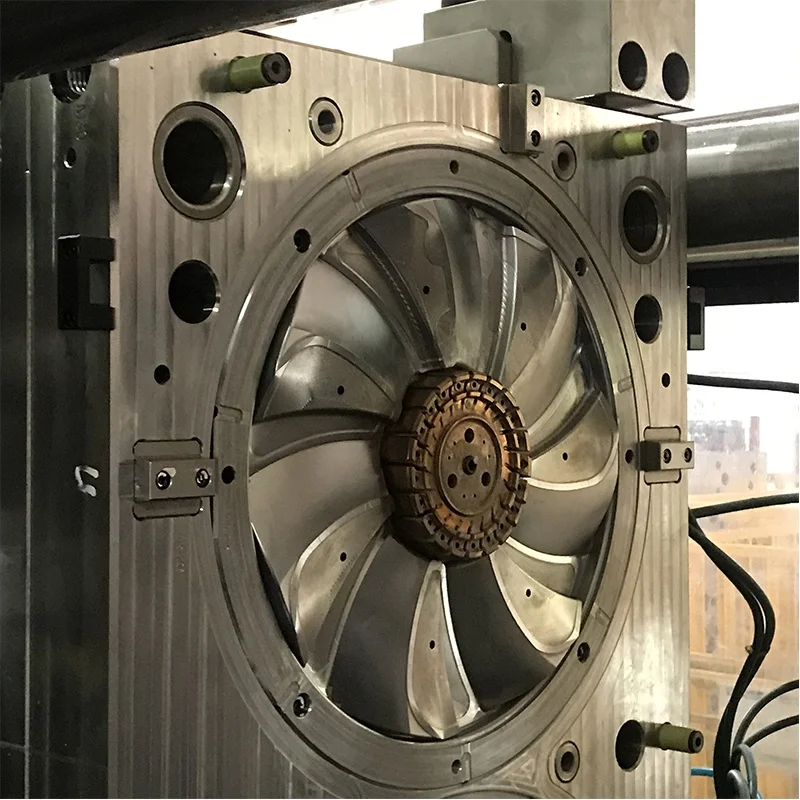

China Household Appliance Fan Blade Die Moulds Builder Tools Manufacturers

Beschreibung

| Plastik: | PP,PPA,PC,Abs,NYLON,CRYLIC,HDPE,POM…etc |

| Steel of Cavity and Core: | Depends on the products,we will show suggestions to customer to choose the suitable material

Commonly use materials as below:

Japanese: NAK80,SKD61,SK53,SKD11,DC53,SKH51,HPM2,etc SCHMOLZ: P20HH,2738,2083H,2343,2344,etc AUS: 1.2738,1.2083,1.2343,1.2344,etc AISI: P20,H13,D2,D6,M2,etc ASSAB: 718HH,Nimax,8402,8407,XW-10,XW-5,EM2,etc |

| Steel of Mold Base: | Depends on product,we will show suggestions to customer to choose the most suitable material. |

| Mold Standard Components: | HASCO,MISUMI,MEUSBURGER,DME,etc |

| Runner: | 1. Hot Runner: Yodoo from Korea; Synventive from Netherland or as you request.

2. Cold Runner |

| Mold Life: | Depends on QTY plan to use suitable steel or as you request Commonly used:

1. 300,000-500,000 shots for one year under normal use procedure for pre-hardness steel material.

2. 500,000 shots for one year under normal use procedure for heat treatment steel material. |

17 Years Rich Experience of Plastic Injection Mould Making and Molding Injection

China Household Appliance Fan Blade Die Moulds Builder Tools Manufacturers

NOTES: We Do Below Service:

1. We Can Export Mould For You Only;

2. We Make Mould & Do Plastic Injection under OEM & ODM;

3. We Make Schimmel & Do Plastic Injection & Semi-Asssemble.

Notes: Our factory is mainly providing Mould Making / Plastic injection molding under OEM/ODM base.

One of our main feature is professionally in making IMD / IML Plastic Parts

Our main products are:

1) Auto parts / Electric motorcycle parts;

2) Medical equipment parts;

3) Consumer Electronics parts;

4) Household Products Parts;

5) Industrial Tool parts;

6) Cosmetic Container Packing Tube or Cap

So our above price is only for your reference. We can quote exact price according to:

1. 3D file or Real Sample for your products; 2. Material you require; 3. Surface treatment requirement

Acryl / PMMA Plastic Parts Made

Cosmetic Container Packaging Tube or Cap made:

Other Plastic Injection Molding Parts

Total Quality Management

Cents was certified with ISO9001 quality system by the International Standards Authority(ISA) in 2008. All the employees took part in the training. The quality responsibility for each department was clarified, and the management procedure was specified. Außerdem, the coordination between the input and output was also defined. Quality manual and program files were compiled. In the future production process, we will insist on continuous improvement to the the key weak link.

Quality Control System

It`s a long process for each product from material purchasing to the final delivery. If an error can not be identified timely, the delivery will get delay, and cause waste on human labor and material etc. To ensure customer get the qualify products,

Cents QC Procedure

1. Part mold draft analysis

2. Mold design control

3. Steel hardness inspection

4. Dimension inspection of electrode ,cavity and core

5. Mold trial report and inspection report

6. PPAP

7. Shipment inspection

Various Safety Package Way Basis on:

Method 1: Shrink film, then bulk loading

Method 2: Shrink film + box + pallet/ wooden case

Method 3: PP + wooden case

Method 4: As per customers’ requirements or negotiated

Packing sizes decided by product sizes

Q.How many molds will your factory make in a month?

EIN. Unser capability is 120 sets-150 sets molds one month;

B. 300,000-3,000,000 pcs plastic injection parts basis on different products.

Q. What’s your mold tolerance?

EIN. 0.005-0.02mm according to different product requirements.

Q. What I should offer to you if I need a quote?

EIN. 2D product drawing & 3D File, or send us real plastic sample.

Q. Which material will your factory use to make a mold?

EIN. Our regular material has NAK80, S136, LKM, DAIDO, HASCO, DME

Q. What’s your delivery time for molds and plastic injection products?

EIN. Our delivery time for mold: 3-5 weeks as mold structure complexity. And our delivery time for plastic injection products: 3-18 Tage.

Q. What we need to provide if we want to start cooperation?

EIN. 1. 3D file or Real sample for your products; 2. Material you require; 3. Surface treatment requirement

Zusätzliche Information

| Herkunftsort: | Guangdong, China |

|---|---|

| Markenname: | OEM Customize mould open |

| Modellnummer: | FM-01 |

| Shaping-Modus: | Kunststoffspritzguss |

| Produktmaterial: | Stahl |

| Produkt: | Household Appliance |

| Produktname: | Household Appliance Fan Blade Die Moulds Builder Tools Manufacturers |

| Mould material: | Steel NAK80;S136… |

| Products materials: | PP,SPORT,TPU,PC,Abs… |

| Leben formen: | 500,000-100,000Schüsse |

| Mould size: | Custom size |

| Cavity: | Custom and will suggest |

| Stichwort: | Custom Plastic injection mould |

| Lieferzeit: | 25-40 days basis on different mould |

| Anwendung: | Household Appliance parts |

| Vorteil: | 16 Jahre Erfahrung |