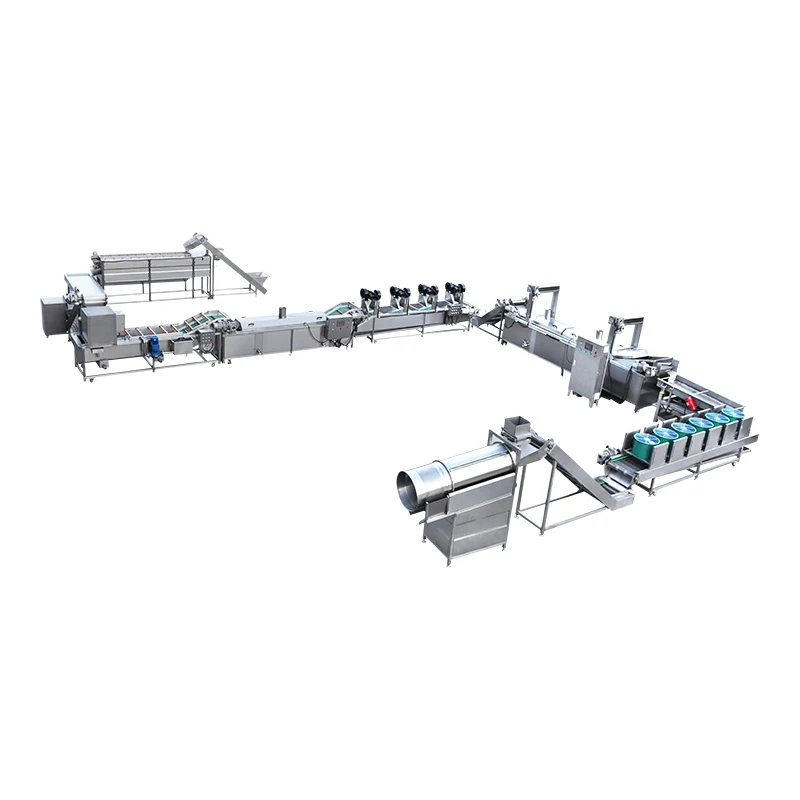

Small Scale Potato Finger Frozen French Fries Making Machine Production Line

Beschreibung

Nein. | Machine Name | Funktion |

1 | PVC Elevator | For elevating and conveying fresh potatoes into the next washing peeling machine |

2 | Potato Washing and Peeling Machine | Thoroughly washing and peeling the potatoes |

3 | Sorting Conveyor | For manually disposing the uncleaned places and selecting the defective potatoes |

4 | Fries Cutting Machine | Cutting the potatoes into fries, sizes adjustable from 7*7 to 12*12mm |

5 | Water Tank Elevator | water as buffer to prevent fries breakage, and simply removing starch, meanwhile elevating fries into next step |

6 | Fries Sorting Machine | Automatically picking up the small pieces fries |

7 | Bubble Washing Machine | Through high pressure waterflow and water bubbles to impact and scrub the fries to wash off the starch |

8 | Blanching Machine | Through 60-95 degree hot water blanching to inhibit the activity of the enzyme and maintains the original vivid color of the fries |

9 | Vibration Dewatering Machine | Through vibration to remove the surface water and also to transport the fries uniformly to the next machine |

10 | Air Drying Machine | Through high pressure wind blowing for pre-cooling and removing the excess water in short time, effectively prevent the fried oil jumped phenomenon |

11 | Elevating Conveyor | For elevating and conveying the fries into next fryer machine |

12 | Continuous Frying Machine | For quick frying the fries around 40 seconds in 180°oil to avoid the adhesion and extend the shelf life |

13 | Vibration Deoiling Machine | Through vibration to achieve deoiling purpose, and also to convey the fries uniformly to next machine |

14 | Pre-cooling Machine | Through high pressure wind blowing for pre-cooling and deoiling the fries |

15 | Freezing Machine | Through mechanical vibration and wind pressure, the fluidized quick freezer floats products on stainless steel mesh belt, frozen products and prevent adhesion, achieve IQF |

16 | Automatic Packing Machine | For packing the finished frozen french fries |

Zusätzliche Information

| Bedingung: | Neu |

|---|---|

| Anwendbare Branchen: | Hotels, Essen & Getränkefabrik, Restaurant, Heimgebrauch, Lebensmittelgeschäft, Essen & Getränkegeschäfte |

| Nach Garantieservice: | Technischer Video-Support, Online-Hilfe |

| Lokaler Servicestandort: | Russland |

| Standort des Ausstellungsraums: | Russland |

| Video Ausgangskontrolle: | Bereitgestellt |

| Maschinenprüfbericht: | Bereitgestellt |

| Marketingtyp: | Neues Produkt 2020 |

| Garantie auf Kernkomponenten: | 1 Jahr |

| Kernkomponenten: | SPS |

| Markenname: | JOYSHINE |

| Herkunftsort: | Henan, China |

| Stromspannung: | 220V/380V |

| Leistung: | 10KW |

| Abmessungen(L*B*H): | 5500*2000*2000mm |

| Gewicht: | 200kg/h |

| Zertifizierung: | CE ISO |

| Garantie: | 1 Jahr |

| Kundendienst bereitgestellt: | Feldinstallation, Inbetriebnahme und Schulung |

| Application fields: | Vegetable processing plant, Commercial catering, Fruit processing plant, Frozen food Factory |

| Machinery Function: | potato chips french fries making production line |

| Rohstoffe: | Frucht, Vegetables, Water |

| Output product name: | Finger Frozen French Fries Making Machine |

| Wichtige Verkaufspunkte: | High Productivity |

| Produktname: | Potato Crisps Production Line |

| Art: | Fully Automatic Processing Line |

| Kapazität: | 100kg/h |

| Feature: | High Efficiency Potato Chips Line |

| Artikel: | Industrial Potatos Chips Fries |

| Anwendung: | Snack Food Production Line |

| Accessory: | Oil Tank And Extra Oil |

| Heating type: | Gas Or Electric |

| Funktion: | Making Fresh Potato Chips |

| Verwendungszweck: | Food Industry Equipment |