CE Certificate Price of Plastic Extrusion Machine

Descripción

CE Certificate Price of Plastic Extrusion Machine

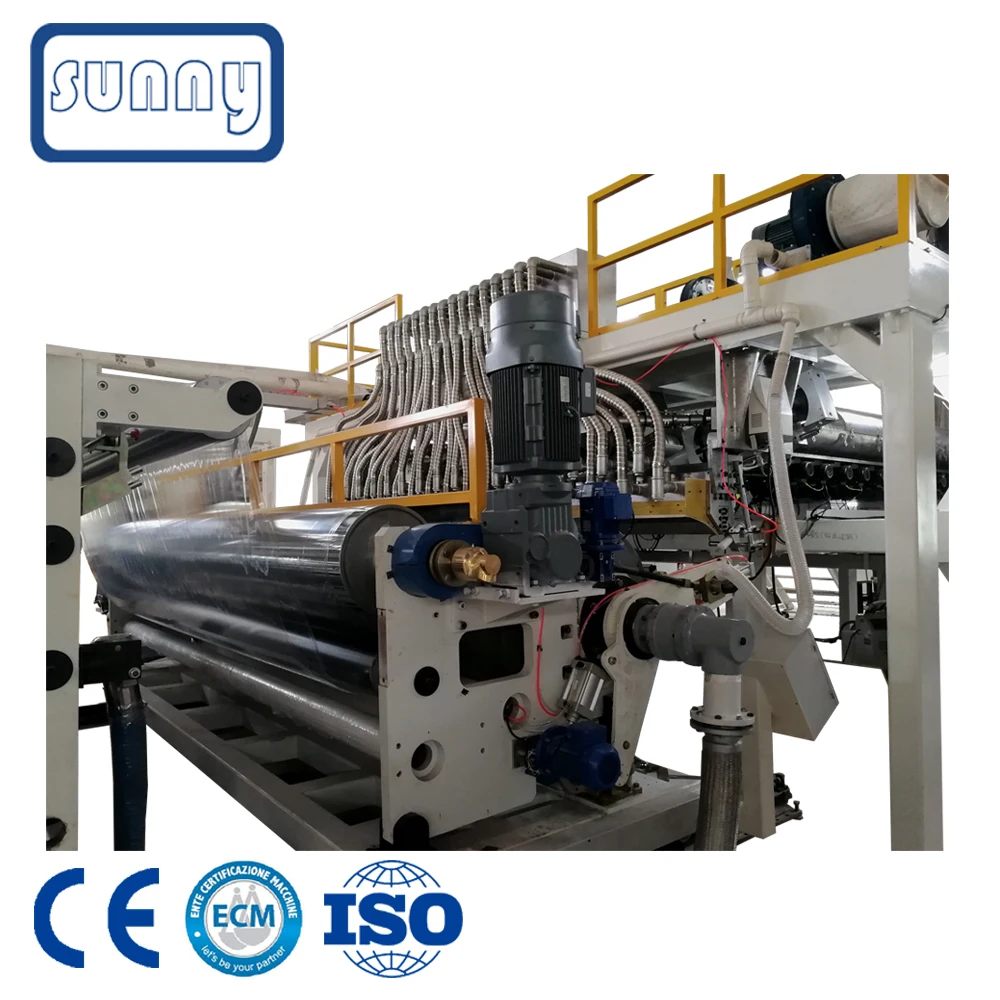

Multi-layer CPP/CPE extruder Casting Film Machine is manufactured and designed by modern advanced technology, since many years manufacturing for casting film machinery and using practical basis, by means of single-layer or multi-layer co-extrusion of CPP, CPE, EVA and high separation barrier film of containing PA, EVOH. It is widely applying for food, embalaje, construction, agriculture etc industries.

Parámetros técnicos

Product category | CPP |

Product structure | A/B/C (1:3:1) |

Product thickness | 20µm—100µm |

Thickness tolerance | less ±4% |

Use raw material | casting level PP material etc. MI=3-10g/min |

Producción | 12 montones / day |

Machine speed | 10-180m/min |

Rolling up diameter | φ800mm |

Product width | 2700milímetro |

Air source | 0—0.8Mpa purification compressed air |

Installed capacity | About 650KW |

Fuente de alimentación | 3 Fase 4 lines 380V / 220V 50Hz, voltage fluctuation less than ±5% |

Basic Composition

| 1 | Automatic lifting material system |

| 2 | Extrusion system |

| 3 | Conector, distributor and DIE molding system |

| 4 | Vacuum chamber, air knift and electric edge position system |

| 5 | Casting cooling system |

| 6 | Online thickness gauge system |

| 7 | Corona treatment and after- cooling system |

| 8 | Traction and full-automatic double working stations rewind system |

| 9 | Online edge trim crushed recycle system |

10 | Electrical control system |

11 | Water temperature control system |

| ||||

|  |  |  |  |

| ||||

How will we do if you place order to us

1. Once we get the deposit, we will arrange purchase raw material immediately, and then take picture to you for checking.

2. We will inform you the progress by picture.

3. What we did, and which part is finalized, we will take picture and let you know.

4. When machine ready, we will take complete machine picture and let you know.

5. What is the delivery date, we will send email to you and let you know.

6. After machine loaded container, we will take picture and let you know.

7. After machine arrive destination, in case some problems, we will try our best to cooperate and support you to solve the problem.

Shantou Sunny Machinery Factory is an integrated professional plant for manufacturing, designing and marketing of Slitting, Rewinding, Laminating, Revestimiento y Multi-layer Casting film machinery facilities for 18 años experience.

Currently, we have a team of high-qualified talents with professional technology, and a team of skilled workers with many years experience for manufacturing flexible package machines. We have professional Mechanical Engineer Department, Assembly Department, Electrical Department, and Software Programming Department. So we can offer customer our standard machinery, also we can customize according to customer specific requirements.

The production mode of professionalization, serialization and standardization have been formed. What’s more, our machinery quality achieved IS09001:2000 international quality management system certification and European Union CE certification. The total quality management and safety production management are improved and standardized.

Información Adicional

| Screw Design: | Triple-screw |

|---|---|

| Número de modelo: | CM-TL3000 |

| Solicitud: | Film |

| Plastic Processed: | PÁGINAS |

| Condición: | Nuevo |

| Lugar de origen: | Guangdong, Porcelana |

| Nombre de la marca: | SUNNY |

| Voltaje: | AC380V/220V±5%,50Hz |

| Dimensión(L*A*A): | 20mx8mx5.4m |

| Peso: | 50ton |

| Certificación: | Certificados CE |

| Servicio posventa proporcionado: | Ingenieros disponibles para reparar maquinaria en el extranjero |

| Energía: | 600kilovatios |

| Calificación automática: | Automático |

| Nombre del producto: | CE Certificate Price of Plastic Extrusion Machine |

| Product structure: | A/B/C (1:3:1) |

| Thickness tolerance: | ≤±4% |

| Use raw material: | casting level PP material etc. MI=3-10g/min |

| Producción: | above 12 montones / day |

| Machine speed: | 10-180m/min |

| Rolling up diameter: | ≤ 800mm |

| Product width: | ≤2700mm |

| Installed capacity: | About 650KW |

| Fuente de alimentación: | 3 Fase 4 lines 380V / 220V 50Hz, voltage fluctuation less than ±5% |