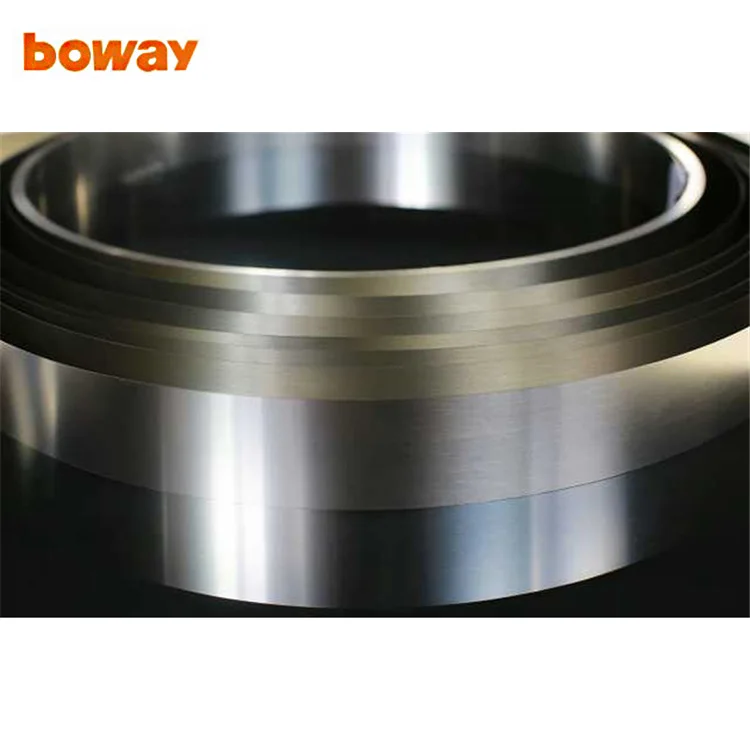

Boway Alloy Copper Alloy Cickel Silver Nickel Strip C75200

La description

Categories: High precision copper alloy strip & plate

Nom: High performance zinc copper alloy nickel strip & plate

Number: C75200

Caractéristique: Elasticity modulus: 115GPa

Good fatigue resistance.

Good electroplate performance

Welding performance is good

Fastness in high temperature

Good cold working, deep drawing, curve performance.

Articles,Chemical composition

| Articles | Chemical composition | |||||

| GB | UNS | DANS | JIS | Cu% | Ni% | Zn% |

| BZn18-26 | C77000 | CuNi18Zn27 | C7701 | 54-58 | 16.5-19.5 | Rem |

Physical properties,fabrication properties

| Physical properties | fabrication properties | |||||||||

| density g/cm3 | electrical conductivity %IACS | thermal conductivity W/(m.K) | modulus of elasticity GPa | specific heat J/(g.K) | cold-workability | machinability | electric plating property | hot dip tin plating property | weldability | corrosion |

| 8.7 | 5 | 32 | 125 | 0.34 | excellent | suitable | excellent | excellent | good | excellent |

Mechanical properties

| Mechanical properties | |||||||||||

| État | Hardness HV | Tension test | bending(in rolling direction)rest | bending(transverse to rolling direction)test | |||||||

| thickness mm | tensile strength MPa | yield strength MPa | elongation% | thickness mm | angles | ID | épaisseur | angles | ID | ||

| 1/2H | 150-210 | 0.1-0.7 | 540-655 | ≥390 | ≥8 | ≤1.6 | 180° | 150% of thickness | ≤0.5 | 180° | 300% of thickness |

| ≥0.71 | 540-655 | ≥390 | ≥11 | ||||||||

| H | 180-240 | 0.1-0.7 | 630-735 | ≥390 ≥500 | ≥4 | ≤1.6 | 180° | 200% of thickness | ≤0.5 | 180° | 400% of thickness |

| ≥0.71 | 630-735 | ≥500 | ≥6 | ||||||||

| EH | 210-260 | ≥0.1 | 705-805 | ≥600 | – | ≤1.6 | 90° | 300% of thickness | ≤0.5 | 90° | 600% of thickness |

| SH | 230-270 | ≥0.1 | 765-865 | ≥680 | – | – | – | – | – | – | – |

Typical application

Shields,Liquid crystal oscillators

Articles,Chemical composition

| Articles | Chemical composition | |||||

| GB | UNS | DANS | JIS | Cu% | Ni% | Zn% |

| BZn18-18 | C75200 | CuNi18Zn20 | C7521 | 62-66 | 16.5-19.5 | Rem |

Physical properties,fabrication properties

| Physical properties | fabrication properties | |||||||||

| density g/cm3 | electrical conductivity %IACS | thermal conductivity W/(m.K) | modulus of elasticity GPa | specific heat J/(g.K) | cold-workability | machinability | electric plating property | hot dip tin plating property | weldability | corrosion |

| 8.73 | 6 | 32 | 125 | 0.34 | excellent | suitable | excellent | excellent | good | excellent |

Mechanical properties

| Mechanical properties | |||||||

| État | Hardness HV | Tension test | bending test | ||||

| Thickness mm | Tensile strength MPa | elongation % | épaisseur | angles | ID | ||

| 0 | – | 0.1-5.0 | ≥375 | ≥20 | ≤1.6 | 180° | sticking closely |

| 1/2H | 120-180 | 0.1-5.0 | 440-570 | ≥5 | ≤1.6 | 180° | 100% of thickness |

| ≤0.5 | 200% of thickness | ||||||

| H | 150-210 | 0.1-0.15 | 540-640 | – | ≤1.6 | 180° | 200% of thickness |

| >0.15-5.0 | ≥3 | ≤0.5 | 400% of thickness | ||||

| EH | ≥185 | 0.1-5.0 | ≥610 | – | – | – | – |

Typical application

Shields,Liquid crystal oscillators,pressing parts

Articles,Chemical composition

| Articles | Chemical composition | |||||

| GB | UNS | DANS | JIS | Cu% | Ni% | Zn% |

| BZn15-20 | C75400 | CuNi15Zn20 | C7541 | 60-64 | 12.5-15.5 | Rem |

Physical properties,fabrication properties

| Physical properties | fabrication properties | |||||||||

| density g/cm3 | electrical conductivity %IACS | thermal conductivity W/(m.K) | modulus of elasticity GPa | specific heat J/(g.K) | cold-workability | machinability | electric plating property | hot dip tin plating property | weldability | corrosion |

| 8.7 | 6 | 32 | 135 | 0.34 | excellent | suitable | excellent | excellent | good | excellent |

Mechanical properties

| Mechanical properties | |||||||

| État | Hardness HV | Tension test | bending test | ||||

| Thickness mm | Tensile strength MPa | elongation % | épaisseur | angles | ID | ||

| 0 | – | 0.1-5.0 | ≥355 | ≥20 | ≤1.6 | 180° | sticking closely |

| 1/2H | 110-170 | 0.1-5.0 | 410-540 | ≥5 | ≤1.6 | 180° | 100% of thickness |

| H | ≥135 | 0.1-0.15 | ≥490 | – | ≤1.6 | 180° | 200% of thickness |

| >0.15-5.0 | ≥490 | ≥3 | |||||

Typical application

Shields,Liquid crystal oscillators

Informations Complémentaires

| Lieu d'origine: | Zhejiang, Chine |

|---|---|

| Taper: | Nickel Strip |

| Noter: | personnalisé |

| Ni (Min): | 45% |

| Résistance (μΩ.m): | personnalisé |

| Powder Or Not: | Not Powder |

| Ultimate Strength (≥ MPa): | / |

| Elongation (≥ %): | / |

| Numéro de modèle: | C75200 |

| Marque: | PW |

| Certificat: | ISO 9001 |

| Nom: | nickel strip |