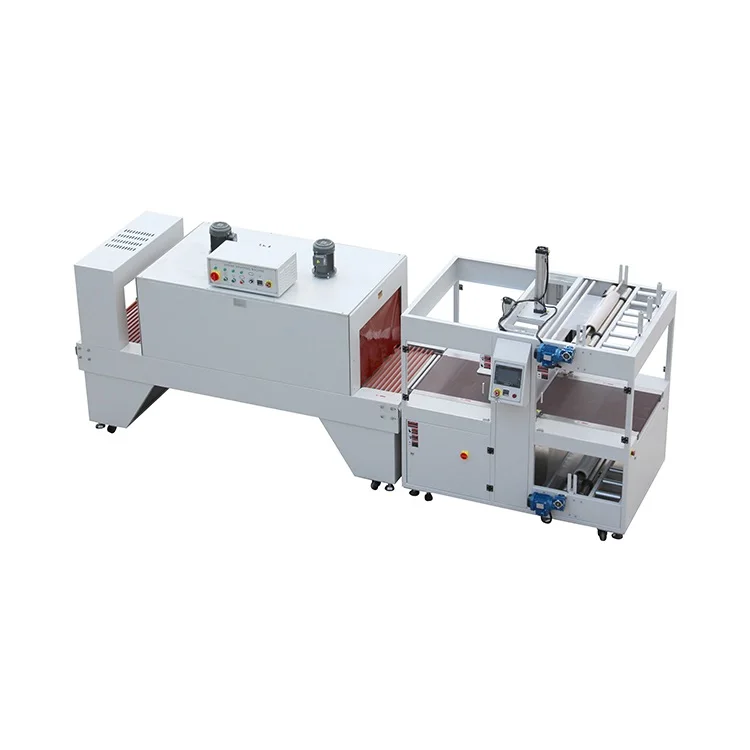

PE film for water bottles sleeve wrapper with 2 holes side and shrinking tunnel machine

Descrizione

GH-6030AZ | SF-6040E | |

Potenza | 2kw | 18kw |

Alimentazione elettrica | AC220V 1/3 PH 50/60Hz | AC220V/380 3 PH 50/60Hz |

Max Packing Size L×W×H | l(unlimited)×500×300mm | W500×H350mm |

Tunnel Size L×W×H | / | 1800×600×400mm |

Blade Length | 670mm | / |

Air Temperature | 0-300℃ | 0-300℃ |

Table Height | 820±50mm | 820±50mm |

Packing Speed | 25m/min. | 0-25m/min |

External Air Source | 6-8kg/cm2 | / |

Film termoretraibile | PE | PE |

Machine Size L×W×H | 950×950×1865mm | 2800×950×1750mm |

Packaging Size L×W×H | 1000×1000×2015mm | 2850×1000×1900mm |

G./N. Il peso | 420/380kg | 625/565kg |

- GH-6030AZS+SF-6040E fully-auto Straight Feeding Sleeve Sealer& Shrink Tunnel adopts the unique linear design and compact structure. It is very suitable for some limited space and don’t need to adjust the forward direction packing. What’s more, there is no length limits;

- It can work independently and also can connect with the production line to realize the unmanned assembly line with the function of auto feeding, film wrapping, sealing, shrinking, cooling and stereotypes.

- The foreign advanced technology and production process make sure the stable performance.

- Siemens “PLC” programmable process controller makes it achieve the mechanical, electrical and pneumatic integration.

- After a special modification, the light and small products can also be packed;

- It has advantages of speed and connection compared with the common side feed machine.

- The sealing line is solid without cracking by cutting and anti- sticking by using special blade.

- Two groups of imported level photoelectric devices are used to accurate positioning;

- The imported conveyor belt is durable and the conveyor speed is controlled by frequency inverter.The user-friendly control box makes the operator’s operation much easier;The pressure device equipped behind the sealing makes sure the position is stable even for the light product during the procession.

- SF-6040E shrink tunnel adopts the imported double recycling motor; so that the hot air in the tunnel is even to have more beautiful shrink effect.

- The outside security cover can be installed according to the customer requirement.

- The chain conveyor made of solid steel covered with imported silicone tube is very durable. Besides the chain conveyor, we also have different conveyors according the products shape and material.

- The frequency inverter controls the speed of the conveyor.

- The separate control box makes sure the electrical components have good ventilation.This machine is mainly applied to the longer products, such as cartons or paper trays which contain drink, beer, acqua, can or glass bottles collection or single shrink wrapping.

Sealer parts | Marca | Country |

Sensor | Autonics | Corea |

Cylinder | Airtac | Taiwan |

Solenoid Valve | Airtac | Taiwan |

Gear Motor | GPG | Taiwan |

PLC | Siemens | Germania |

HMI | Siemens | Germania |

Film Motor | Haitec | Italia |

Intermediate Relay | Siemens | Germania |

Temperature Controller | Autonics | Corea |

Alimentatore a commutazione | Schneider | Francia |

Overload Relay | Schneider | Francia |

AC Contactor | Schneider | Francia |

Frequency Inverter | Schneider | Francia |

Tunnel Parts | Marca | Country |

Gear Motor | GPG | Taiwan |

Circulation Motor | SURFON | Taiwan |

Intermediate Relay | Siemens | Germania |

Temperature Controller | Autonics | Corea |

Alimentatore a commutazione | Schneider | Francia |

Overload Relay | Schneider | Francia |

AC Contactor | Schneider | Francia |

Frequency Inverter | Schneider | Francia |

Video Link | Prodotto |

https://youtu.be/4XmJDP7no4E | Original life rice-pudding boxes |

https://youtu.be/ji869r4e39c | Speed test |

https://youtu.be/ji869r4e39c | Lobster Foam box |

Informazioni aggiuntive

| Tipo: | Wrapping Machine |

|---|---|

| Packaging Type: | Cartons, CANS, Bottiglie, Barrel, Stand-up Pouch, Borse, Film, Foil, Belt, Pouch, Capsule, Astuccio |

| Driven Type: | Elettrico |

| Packaging Material: | Film |

| Industrie applicabili: | Hotels, Garment Shops, Negozi di materiale da costruzione, Stabilimento di produzione, Officine di riparazione macchine, Cibo & Beverage Factory, Fattorie, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Lavori di costruzione , Energia & Mining, Cibo & Beverage Shops, Advertising Company |

| Dopo il servizio di garanzia: | Supporto tecnico video, Supporto online, Pezzi di ricambio, Servizio di manutenzione e riparazione sul campo |

| Posizione del servizio locale: | Egypt, Canada, Tacchino, Regno Unito, stati Uniti, Italia, Francia, Germania, Viet Nam, Philippines, Brasile, Peru, Saudi Arabia, Indonesia |

| Posizione dello showroom: | Egypt, Canada, Tacchino, Regno Unito |

| Condizione: | Nuovo |

| Applicazione: | Cibo, Bevanda, Commodity, MEDICAL, Chemical, Macchinari & Hardware, APPAREL, Textiles |

| Grado automatico: | Automatico |

| Voltaggio: | 380/220v |

| Luogo d'origine: | Cina |

| Marchio: | kuko |

| Dimensione(L*L*A): | 1628*1262*1885mm+2800*950*1750mm |

| Il peso: | 1045kg |

| Certificazione: | ISO CE |

| Servizio post-vendita fornito: | Supporto online, Supporto tecnico video, Ricambi gratuiti, Installazione sul campo, messa in servizio e formazione, Servizio di manutenzione e riparazione sul campo |

| Garanzia: | 1 Anno |

| Punti chiave di vendita: | Automatico |

| Tipo di marketing: | Nuovo prodotto 2020 |

| Rapporto di prova del macchinario: | Fornito |

| Video ispezione in uscita: | Fornito |

| Garanzia dei componenti principali: | 1 Anno |

| Componenti principali: | PLC, Pressure vessel, Gear, Il motore, Motore, Cuscinetto, Gearbox, Pump |

| Nome del prodotto: | Factory Sleeve Shrink Wrap Packing machine |

| Packing speed: | 15m/min. |

| Massimo. package size: | 300 X 500 x 300mm |

| Funzione: | shrink PE film |