Uitverkoop!

BT40 angle head with coolant CAT40 CAT50 ISO40 SK40 BT50 FMB63 90 degree angle head ER16 ER20 ER25 ER32 ER40 angle head

Beschrijving

product beschrijving

Machine Tools Accessories 90 degree angle head for CNC BT30 BT40 BT50 CAT30 CAT40 CAT50 SK30 SK40 SK50 FMB22 FMB27 FMB32 ER16 ER25 ER32 ER40 ER50 angle head CNC angle head BT40 angle head with coolant 90 degree angle head angle head

Angle head with coolant

Merk: OLICNC

Maat :AG90-ER25-60

Stroom: 1.5k

Snelheid:4500toeren

Maximum pressure: 1.0MP

OEM customization: steun

Voorbeeld bestelling: beschikbaar

Avalible: SK/CAT/BT/KM/ISO/HSK

Chip fluid can cool the body at the same time

Four unique advantages make good products

● Japanese high-precision angular contact ball bearings

● Germany high precision sector gear

● The unique sealed structure is more

effective in preventing dust and water ● Corresponds to the tip oiling angle.

!!! All angle heads have passed precision test and rotation test.

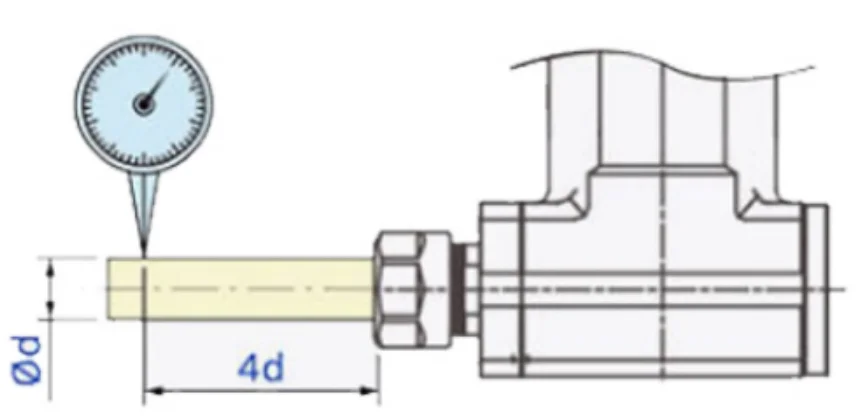

TIR: 0.005mm at holder nose and 0.008mm at 4d

Productparameters

Model | Uitgang | L1 | L2 | L3 | Stroom | Maximum snelheid | Maximum torque | Reduction ratio |

AG90- ER16-60 | ER16 | 41/48 | 65/80 | 60 | 1.5kW | 4500RPM | 1 2NM | 1:1 |

AG90-ER16-120 | ER16 | 41/48 | 65/80 | 120 | 1.5kW | 4500RPM | 1 2NM | 1:1 |

AG90-ER16-180 | ER16 | 41/48 | 65/80 | 180 | 1.5kW | 4500RPM | 1 2NM | 1:1 |

More size information please contact us.

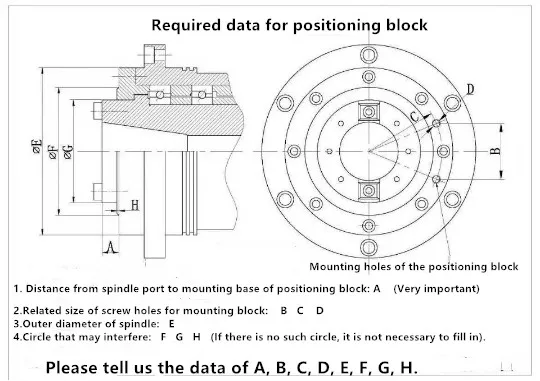

Buy Angle Head Gift Positioning Block

Please provide your spindle parameters.

Details Afbeeldingen

Precautions for using angle milling head

1. Check whether the weight of the angle milling head meets the requirements of the machine tool magazine

Weight requirements. (If it does not meet the recommended manual installation angle milling head)

2. Check the tightening of the angle milling head before the completion of installation and processing

Whether the bolts are loose.

3. Check whether the positioning pin of the angle milling head fits tightly with the groove of the fixing block solid.

4. Check whether the limit pin is completely separated from the positioning ring before use.

5. Do not use angle milling head for continuous processing for a long time, it is recommended to process 2 Shut down for 5 minutes after two hours to prevent the internal bearing teeth of the angle head Overheating of internal parts such as wheels. (If you need to add It is recommended to purchase multiple angle milling heads for replacement.)

6. Need to inject a little lubricating grease with an oil gun every week to lubricate the teeth

7. Anti-rust treatment is required when the angle milling head is not used.

8. It is strictly forbidden to use a speed exceeding the maximum speed range of the angle milling head, Over het algemeen, the maximum speed is within 70%, and the maximum speed can be used in a short time Rotating speed.

9. It is strictly forbidden to vigorously strike the angle milling head shell to prevent internal bearing teeth Parts such as wheels will be broken.

10. When using an angle milling head, the input shank and output cone must be maintained Cleanliness.

11. Bottom pad before installation. One cushion pad to prevent angle milling head Falling hurts.

Weight requirements. (If it does not meet the recommended manual installation angle milling head)

2. Check the tightening of the angle milling head before the completion of installation and processing

Whether the bolts are loose.

3. Check whether the positioning pin of the angle milling head fits tightly with the groove of the fixing block solid.

4. Check whether the limit pin is completely separated from the positioning ring before use.

5. Do not use angle milling head for continuous processing for a long time, it is recommended to process 2 Shut down for 5 minutes after two hours to prevent the internal bearing teeth of the angle head Overheating of internal parts such as wheels. (If you need to add It is recommended to purchase multiple angle milling heads for replacement.)

6. Need to inject a little lubricating grease with an oil gun every week to lubricate the teeth

7. Anti-rust treatment is required when the angle milling head is not used.

8. It is strictly forbidden to use a speed exceeding the maximum speed range of the angle milling head, Over het algemeen, the maximum speed is within 70%, and the maximum speed can be used in a short time Rotating speed.

9. It is strictly forbidden to vigorously strike the angle milling head shell to prevent internal bearing teeth Parts such as wheels will be broken.

10. When using an angle milling head, the input shank and output cone must be maintained Cleanliness.

11. Bottom pad before installation. One cushion pad to prevent angle milling head Falling hurts.

Our Package

gerelateerde producten

Inpakken&Verzenden

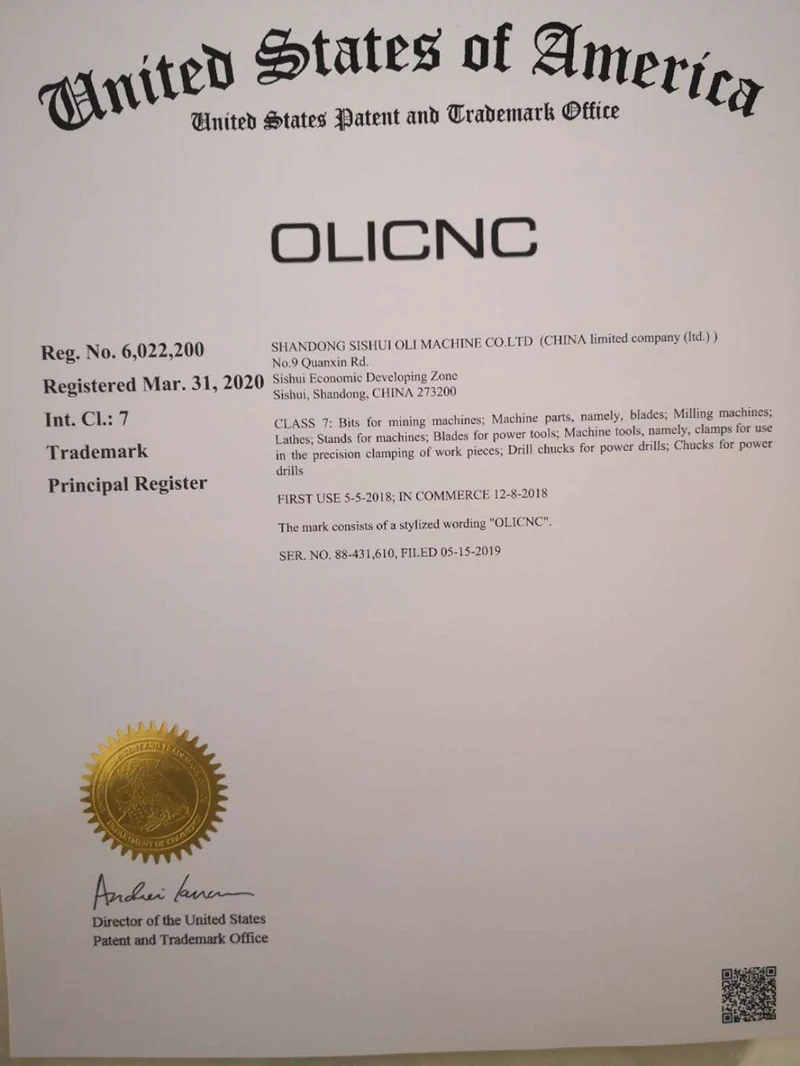

Certificeringen

Our company

OLICNC® came into the line of Machine Tool Accessories in 1988, OLICNC® was legally registered in 2004; Bought land at No. 9

Quanxin Rd., Sishui Economic Developing Zone, Jining, Shandong in 2007 and built new factory on it, occupies an area of 15320㎡,

workshops and office building are over 11000㎡. Nu OLICNC® consists of related

Quanxin Rd., Sishui Economic Developing Zone, Jining, Shandong in 2007 and built new factory on it, occupies an area of 15320㎡,

workshops and office building are over 11000㎡. Nu OLICNC® consists of related

technologie, processing, trading and service, as a professional company to serve for our clients, employees and society entirely.

OLICNC® mainly manufactures Tool Holders for machine tools & Components for wood-working machines, as well as local Machine

Accessoires, belongs to the line of Machine & Tools. OLICNC® main products are necessary Tool Holders in lathing, milling,

drilling, slijpen, boring, planning, CNC Machines or Machine Centers, including variety of Spring Collets, Collets Chuck Sets,

Mill

Houders, Tapping Collets, Rough or Precision Boring Heads, Drill Chucks, Live Centers and so on. In de tussentijd, OLICNC® can alsosupply

Machine Accessories like Lathe Chucks,

Accessoires, belongs to the line of Machine & Tools. OLICNC® main products are necessary Tool Holders in lathing, milling,

drilling, slijpen, boring, planning, CNC Machines or Machine Centers, including variety of Spring Collets, Collets Chuck Sets,

Mill

Houders, Tapping Collets, Rough or Precision Boring Heads, Drill Chucks, Live Centers and so on. In de tussentijd, OLICNC® can alsosupply

Machine Accessories like Lathe Chucks,

Steel Clamping Kits,Machine Vises, Bench Vises, Dividing Heads, Rotary Tables and Magnetic Chucks., enz. Additional HSS Thread Tools and Tool Bits can be supplied. All these items from OLICNC® are in series of different common sizes; Besides above exiting ones, OLICNC® can also make and supply the goods as delivered samples of drawings.our company website: www.olimachine.com Shandong Sishui OLI Machine Co., Ltd Add.: No.9 Quanxin Rd. Sishui Economic Developing Zone, Jining, Shandong, China Tel: ++86-537-4252090

MP:+8615163782196 Fax:++86-537-4255482

TradeManager:cn1510666465

MP:+8615163782196 Fax:++86-537-4255482

TradeManager:cn1510666465

Extra informatie

| plaats van herkomst: | Shandong, China |

|---|---|

| Voorwaarde: | Nieuw, Nieuw 90 degree angle head |

| Toepasselijke industrieën:: | fabriek:, Machinery Repair Shops |

| Na garantieservice: | Online hulp |

| Lokale servicelocatie: | Geen |

| Showroomlocatie: | Geen |

| Video uitgaande inspectie: | Mits |

| Machinetestrapport:: | Mits |

| Marketingtype:: | Nieuw product 2020 |

| Merknaam: | OLICNC |

| Modelnummer: | M12 clamping kit 90 degree angle head |

| Garantie: | 6 maanden |

| Dienst na verkoop geleverd: | Online hulp |

| Kern onderdelen: | Nee |

| Model: | angle head |

| Sizes: | AG90-ER16-60 |

| Merk: | OLICNC 90 degree angle head |

| Inpakken: | Aluminum plastic box 90 degree angle head |

| Betaalvoorwaarden: | Ali Baba;T/T 90 degree angle head |

| Tijd om te bezorgen: | 7 dagen 90 degree angle head |

| Steekproef: | Accepatable 90 degree angle head |

| MOQ:: | 2 sets 90 degree angle head |

| Kleur: | blauw 90 degree angle head |