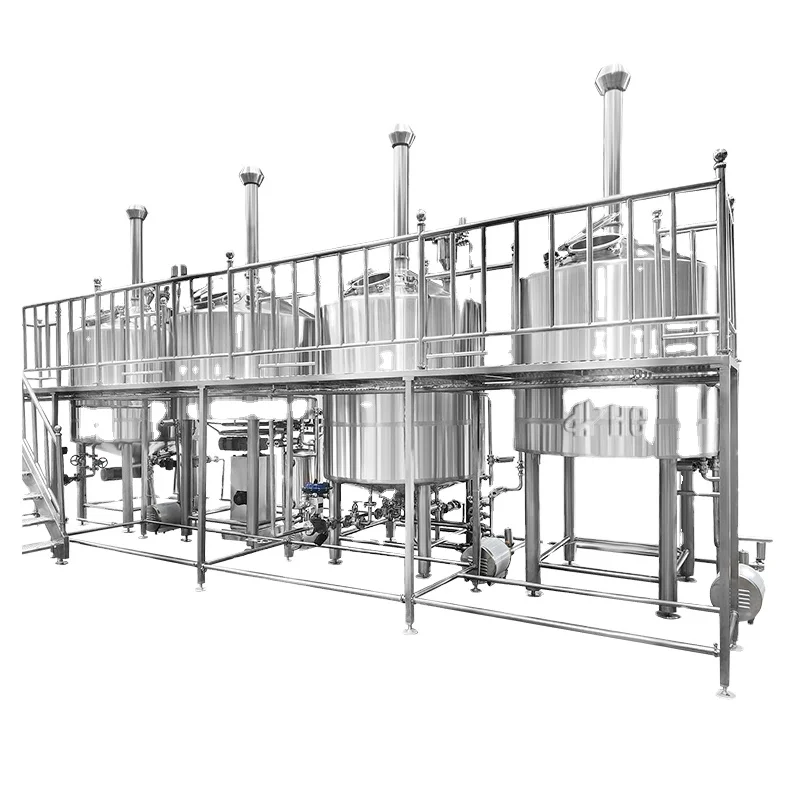

2000L turnkey project of brewery plant commercial beer Manufacturing turnkey brewery system brewing beer equipment

Description

Model | HG-NZ-2000 |

Capacity | 2000L/Batch |

Material | SUS 304 |

Combination method | Mash/lauter tun, kettle/whirlpool tank |

Application | Restaurants, bars, hotels, brewery |

Heating way | Electric heating/Steam heating/Direct fire heating |

Voltage | AC380/220V,50/60HZ |

Water consumption | 4m3/T |

Floor area | 10m2 |

Degree of automation | Fully automatic |

2.Good abrasion resistance materialcopper beer equipment.

3.We all adopt SUS304 to produce our equipment. The inner jacket and seal head of the tanks are all 3.0mm. The external jacket is 2.0mm. It ensure the good pressure resistance and good abrasion resistance.

4.Polishing accuracy up to Ra0.4μ m .

5. Strict tank pressure test.

6. Energy conservation and pollution emissions.

Item | Production capacity | Volume in US Gallon | Heating area | Tank diameter | Height |

HG-50 | 50L/day | 14US Gallon | 0.15㎡ | 550mm | 1500mm |

HG-100 | 100L/day | 26US Gallon | 0.25㎡ | 650mm | 2000mm |

HG-200 | 200L/day | 53US Gallon | 0.25㎡ | 850mm | 2200mm |

HG-300 | 300L/day | 79US Gallon | 0.3㎡ | 950mm | 2500mm |

HG-500 | 500L/day | 132US Gallon | 0.5㎡ | 1160mm | 2800mm |

HG-600 | 600L/day | 158US Gallon | 0.6㎡ | 1220mm | 2350mm |

HG-700 | 700L/day | 185US Gallon | 0.7㎡ | 1250mm | 2380mm |

HG-800 | 800L/day | 212 US Gallon | 0.8㎡ | 1260mm | 2400mm |

HG-1000 | 1000L/day | 264US Gallon | 1.0㎡ | 1360mm | 3000mm |

HG-1500 | 1500L/day | 396US Gallon | 1.5㎡ | 1520mm | 2900mm |

HG-2000 | 2000L/day | 528US Gallon | 2.0㎡ | 1760mm | 3150mm |

HG-2500 | 2500L/day | 660US Gallon | 2.5㎡ | 1800mm | 3200mm |

HG-3000 | 3000L/day | 792US Gallon | 3.0㎡ | 1860mm | 3800mm |

HG-5000 | 5000L/day | 1320US Gallon | 5.0㎡ | 2260mm | 4400mm |

The PLC or digital dispalyer could control the temperature by connecting with the PT 100sensor.The brewing tanks with rock wool to keep warm,the fermenters and bright beer tank with PU as cooling jacket to keep cool.

2.Which countries your products are exported to?

Our stainless steel microbrewery equipment are sold all over the world and with related certifications.

3.How to use your machine?

We have paper instructions in English, and we will teach till you do it well.

4.How long is your delivery time?

Usually it takes about 30 working days to manufacture a brewery.Depending on the size of the brewery,the amount of custom designed equipment,our general workload and the way of shipping this period can be shorter or longer.

5.Do you provide after-sales service?

Yes,we could provide after-sales service.We have many professional engineers, they can go to your place and teach your person installation and brewing.

-3D effective sketch: We will 3D effective sketch to make sure ensure you have a more intuitive experience

adjust the machines for you. He can also train your staff to use the equipment.

Additional information

| Processing: | Fermenting Equipment |

|---|---|

| Applicable Industries: | Food & Beverage Factory, Restaurant, Food & Beverage Shops, Breweries |

| After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location: | United States, France |

| Showroom Location: | Canada, Turkey, United Kingdom, Italy, France, Germany, Viet Nam, Philippines, Brazil, Indonesia, India, Russia, Spain, South Korea, Chile, UAE, Colombia, Romania, Bangladesh, South Africa, Ukraine, Kyrgyzstan, Japan, Malaysia, Australia |

| Condition: | New |

| Place of Origin: | Shandong, China |

| Brand Name: | HG |

| Processing Types: | Alcohol |

| Voltage: | According to client's need |

| Power: | According to client's need |

| Dimension(L*W*H): | According to client's need |

| Weight: | According to client's need |

| Certification: | CE ISO TUV |

| Warranty: | 3 years |

| After-sales Service Provided: | Field installation, commissioning and training, Engineers available to service machinery overseas |

| Machinery Test Report: | Provided |

| Warranty of core components: | 3 years |

| Core Components: | Gearbox, Motor, PLC |

| Key Selling Points: | Easy to Operate |

| Marketing Type: | New Product 2020 |

| Video outgoing-inspection: | Provided |

| Material: | SUS304 |

| Usage: | Beer Brewing |

| Cooling way: | Dimple plate cooling |

| Capacity: | 2000L |

| Thickness of inner jacket: | 3mm |

| Welding: | TIG Welding |

| Insulation Materials: | PU Foma Insulation |

| Polish: | Ra0.4 |

| Control system: | PLC |