Sale!

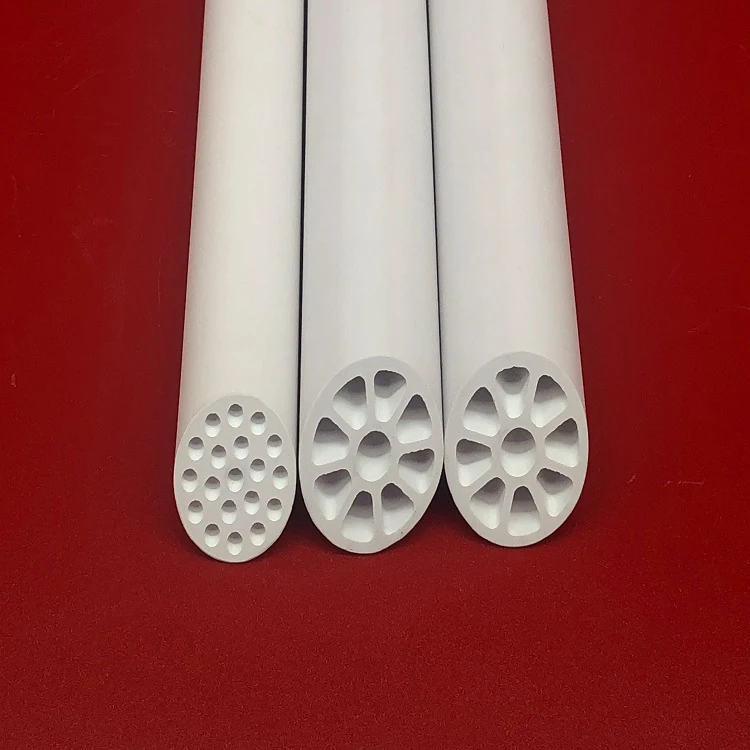

Aluminum Oxidant Based Tubular Microfiltration Ceramic Ultrafiltration Membrane Filter

Description

Products Description

Ceramic microfiltration membrane element is made from alumina and zirconia which is an asymmetric membrane structure with multi-channel tubular shape. The pore is on the channel. Driven by operation pressure, the liquid is running in the membrane. The part less than pore size is permeation, the part lager than pore size is concentrated liquid, so as to achieve the separation, concentration and purification purposes.

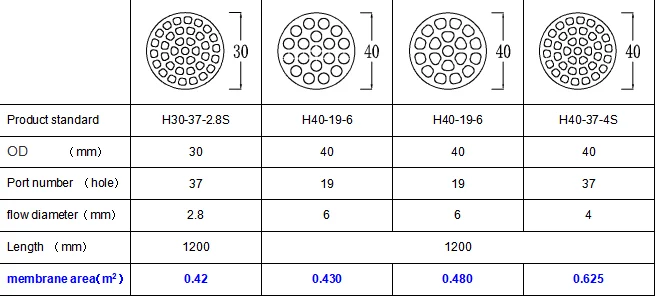

Ceramic membrane | Model | CMF19040 CMF37036 | |

Raw Material | α-Alumina/Zirconia | ||

Pore size | 50 nm, 100nm,200nm | ||

Length | 1200 mm | ||

Membrane area(㎡) | 0.155, 0.235, 0.246, 0.257, 0.275, 0.286, 0.320, 0.420, 0.430, 0.480, 0.625 | ||

Outside diameter | 30 mm, 40mm | ||

Channel Diameter | 4.0 mm, 3.6mm | ||

Construction | Multi-channel tubular element | ||

Operating conditions | Typical Operating Pressure | 29-145 psi (2-10 bar) | |

Maximum Operating Temperature | 302°F (150°C) | ||

Maximum Cleaning Temperature | 176°F (80°C) | ||

Allowable pH – Continuous operation | 0-14 | ||

Allowable pH – Clean-In-Place (CIP) | 0-14 | ||

Features | Exceptional mechanical resistance | ||

Wide chemical and pH compatibility(0-14) | |||

Excellent thermal stability | |||

Cross-flow filtration | |||

Excellent inorganic materials | |||

Company Profile

Company Advantage

FAQ

Payment & Shipping

Additional information

| Place of Origin: | Fujian, China |

|---|---|

| Brand Name: | DMD |

| Ceramic membrane outside diameter: | 30 mm, 40mm |

| Ceramic membrane pore size: | 50 nm, 100nm, 200nm |

| Ceramic membrane length: | 1200 mm |

| Ceramic membrane channel diameter: | 4.0 mm, 3.6mm |

| Typical Operating Pressure: | 29-145 psi (2-10 bar) |

| Maximum Operating Temperature: | 302°F (150°C) |

| Maximum Cleaning Temperature: | 176°F (80°C) |

| Allowable pH - Continuous operation: | 0-14 |

| Allowable pH - Clean-In-Place (CIP): | 0-14 |

| Feature: | Exceptional mechanical resistance, Cross-flow filtration |