Sale!

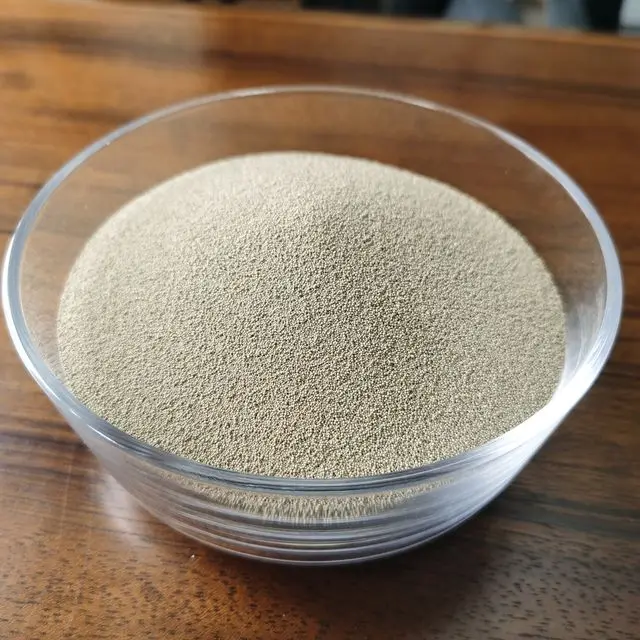

China High Refreactoriness Sintered Ceramic sand For Foundry Application

Category: Other Non-Metallic Minerals & Products

Description

Product Introduction

SINTERED CERAMIC SAND FOR FOUNDRY

Sintered Ceramic Sand(SCS) is our newly developed artificial sand for the use of foundry.

It contains 55-60% Mullite, 20-30%Corrundum, 5-10% Amorphous in material phase. Advantages as following:

REDUCED PENETRATION AND BURN-IN · THERMAL EXPANSION CONTROL ·

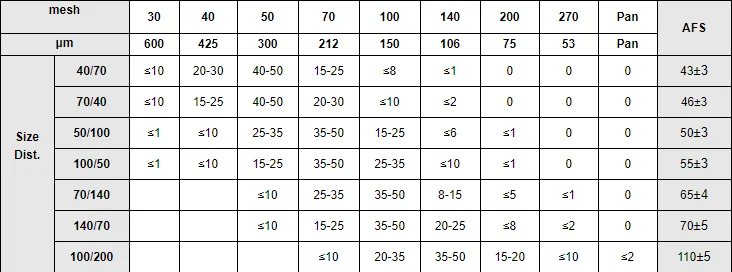

REDUCED WASTE AND HEALTH HAZARD · WIDE CHOICE OF PARTICLE SIZE ·

HIGH RECLAMATION YIELD

Available in standard AFS sizes, also including custom blending.

It has been engineered specifically for foundries to provide the best performance in various types of castings.

Aluminum, gray and ductileiron, steel, copper, magnesium and other metals can be made using most any resin systems including phenolic urethanes, phenolicester, furan, sodium silicate, bentonite clays, shell resins and alkyd oils.

Product Parameters

Chemical and Physical Properties

Composition | Al2O3 | SiO2 | Fe2O3 | TiO2 | Others |

% | ≥53 | ≤34 | ≤3.5 | ≤3.0 | ≤2.5 |

PH | Bulk Density/cm3 | True Density/cm3 | Refractoriness℃ | Thermal Expansion(1200℃) | Acid Cost,% | L.O.I.,% |

7-8 | 1.48-1.62 | 2.7-2.8 | 1800 | (4.5-6.5)*10-6/k | ≤2 | ≤0.1 |

Product Advantages

Sintered Ceramic Sand(SCS) has been selected and used in foundries as a result of its unique combination of properties.

The properties listed below generally result in a better surface finish and reduced likelihood of casting defects.

Sintered Ceramic Sand(SCS) outperforms specialty sands and at the same time offers distinct economic advantages.

Sintered Ceramic Sand(SCS) has a lower thermal expansion, resulting in higher precision and accuracy of castings while also leading to lower scrap cost and lower cost to correct inaccuracies. Its greater flowability increases the ability to produce thin wall castings and minimizes casting mass.

With lower density than other specialty media, Sintered Ceramic Sand(SCS) requires less product (by weight) to produce an equal volume of cores or molds. It also provides lower cost per cubic foot of product used. Also, the strength and durability of Sintered Ceramic Sand(SCS) enhances reclamation and reduces media consumption.

Sintered Ceramic Sand(SCS) is inert and contain no quartz silica.

Sintered Ceramic Sand(SCS), versus silica sand, has a lower thermal expansion, resulting in higher precision and accuracy of castings while also leading to lower scrap cost and cost to correct inaccuracies. It reduces the occurrence of casting defects such as veining, penetration and burn-‐on, resulting in lower cleaning cost. Its low thermal expansion and greater flow properties increase the ability to produce thin wall, complex castings and minimize casting mass.

Sintered Ceramic Sand(SCS) has a lower thermal expansion, resulting in higher precision and accuracy of castings while also leading to lower scrap cost and lower cost to correct inaccuracies. Its greater flowability increases the ability to produce thin wall castings and minimizes casting mass.

With lower density than other specialty media, Sintered Ceramic Sand(SCS) requires less product (by weight) to produce an equal volume of cores or molds. It also provides lower cost per cubic foot of product used. Also, the strength and durability of Sintered Ceramic Sand(SCS) enhances reclamation and reduces media consumption.

Sintered Ceramic Sand(SCS) is inert and contain no quartz silica.

Sintered Ceramic Sand(SCS), versus silica sand, has a lower thermal expansion, resulting in higher precision and accuracy of castings while also leading to lower scrap cost and cost to correct inaccuracies. It reduces the occurrence of casting defects such as veining, penetration and burn-‐on, resulting in lower cleaning cost. Its low thermal expansion and greater flow properties increase the ability to produce thin wall, complex castings and minimize casting mass.

The high roundness and sphericity of Sintered Ceramic Sand(SCS), enhance flow properties. The durability resists breakdown and media consumption while promoting reclamation thus lowering the cost associated with transportation, disposal and replacement.

Product Packing

Manufacturing Technique

Customer Photos

Additional information

| Place of Origin: | Henan, China |

|---|---|

| Brand Name: | RM |

| Model Number: | FCS |

| Application: | foundry |

| Shape: | beads |

| Chemical Composition: | Al2O3 50-60% |

| color: | brown |

| Usage: | foundry |

| Package: | jumbo bags |

| Material: | bauxite,kaolin |

| Name: | cerabeads ceramic sand |

| Grade: | AFS |

| Melting Point: | 1800 |

| Advantages: | good performance |

| Type: | sintered |

| Density: | 1.48-1.62g/cm3 |