Sale!

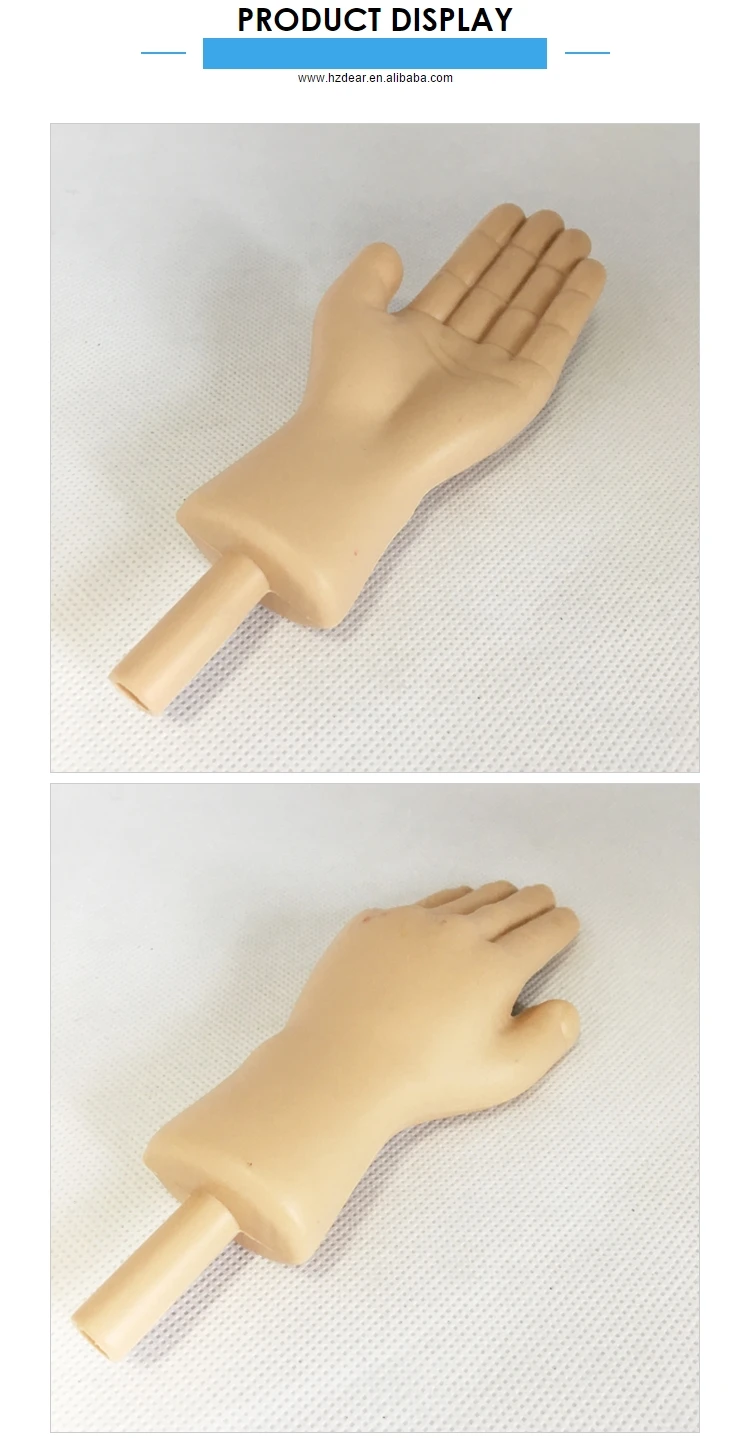

Customized DIY Finger PP Plastic Toy

Description

| Product Name | Custom Household Manufacturing Plastic Injection Moulding | Experience | Over 30 years of experiences |

| Material | ASB,PP,PE,Nylon,PC etc. | Shape | Custom sizes |

| Manufacturing Process | Plastic Injection Moulding | Package | Standard or customized |

| Design Software | SolidWorks | Delivery | 2-3 days for samples, bulk depend on qty |

| Prototyping Soltuion | Material | Features |

| ODM design | Products ODM design, 2D, 3D drawing, mold design | Professional, efficience, and listening |

| Plastic injection | ABS,POM,PP,PU,PC,PA66,PMMA,PVC…etc | It”s neccessary to make a mold at first, but it”s the cheapest way to make plastic product in big quantity. Most of the plastic parts from market is made by plastic injection |

| 3D Printing | A wide variety of plastic and metal material options. | Compare to plastic injection, it”s more cheaper and efficience in small quantity; compare to CNC, it”s much cheaper but with less precision |

| Computer Numerical Control (CNC) | A wide variety of plastic and metal material options. | High precision in parts, can be a supplementary way for plastic injection and 3D printing |

| Surface Treatment: | Painting, laser texture, chrome finish, powder coating, electroplating | Proper for plastic and metak parts |

| Assembly & Test | Most of the plastic / metal / electronic parts assembly and test | We have a lot of experience to assembly and test many whole project, so satisfied by our client |

| Mould material | P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136, etc . |

| Mould type | Injection plastic mould |

| Product material | ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE,etc |

| Standard | HASCO, DME, MISUMI, JIS, LKM, etc. |

| Mould tooling equipment | Lathe,Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine |

| Maximum mould size | 1500*1500 mm |

| Gate | Side Gate, Sub Gate, Direct Gate, Hook Gate, Pin Point Gate, etc. |

| Cavity | Single or Multi cavities |

| Mould Life | 45#:300,000 to 500,000 shots |

| P20:600,000 shots | |

| 718: 800,000shots | |

| Lead time | About 3-4 weeks |

| Package | Wooden packing box or as customer’s requirements |

Q1: What type of plastic is best for my design/product?

A1: Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Q2: What type of mould tool do I need?

A2: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q3: I”ve decided to go ahead with my project. How long will it take to get my parts?

A3: It takes 3-5 weeks to have the mould tool manufactured depending on the part”s complexity and the number of cavities (single or multi). After we received final approval by you of the new tool, you can expect delivery of parts within 3-5 days.

Q4: Can you produce according to the samples?

A4: Yes, we can produce by your samples or 2D/3D technical drawings.

Q5: Do you provide samples? Is it free or extra?

A5: Yes we offer free sample but do not afford the shipping cost.

Additional information

| Place of Origin: | Zhejiang, China |

|---|---|

| Brand Name: | OEM |

| Model Number: | M170516 |

| Type: | Other Classic Toys |

| Product Name: | Customized DIY Finger PP Plastic Toy |

| Usage: | For toys |

| Process: | Injection Plastic Moulding |

| Service: | Welcome OEM/ODM service |

| Feature: | High Precision, low tolerance, custom made |

| Advantage: | R&D ability, FREE design, All in one solution |

| Package: | Customized or standard cartons with shipping marks |

| Delivery: | 3-4 weeks for the moulds, 3-5 days for samples after mould finish |

| Design Format: | 2D or 3D drawings IGS or STP file |

| Difference: | Customized, unique design, one-stop service |