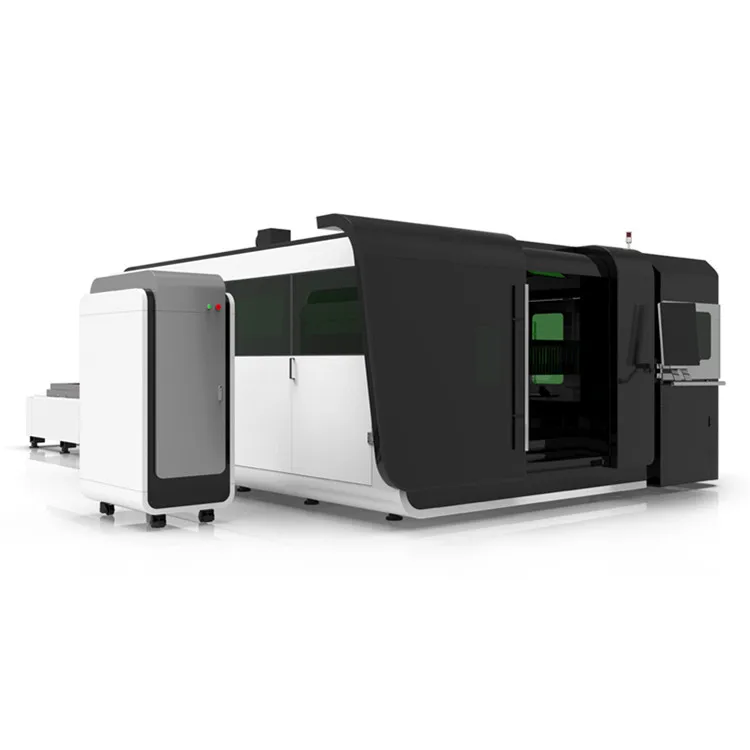

Gweike LF4020GAR fiber laser cutting machine 4kw

Description

between us and foreign developed region is getting smaller and smaller.

Meanwhile fiber laser cutting machine also has brought a lot of innovation ideas to the sheet processing industry.As laser

technology develops rapidly, fiber laser cutting machine has occupied the metal processing market in the global.

Material | 1kw | 2kw | 3kw | Gas |

carbon steeel | 10mm | 18mm | 22mm | Oxygen |

stainless steel | 5mm | 8mm | 10mm | Nitrogen |

aluminum | 3mm | 5mm | 8mm | Nitrogen |

Product Application:

fiber laser cutting machine as one classic model, widely used in many common areas of our life, such as processing of stainless steel kitchenware, storage cabinet and other cabinets, is closely related to people’s daily life.

Used for cutting a variety of metal plates, pipes (add pipe cutting device), mainly used in stainless steel, carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, various alloy plate, rare metal and other metal materials.

With a fully enclosed design. The observation window adopts an European CE Standard laser protective glass. The smoke produced by

cutting can be filtrated inside, it’s non-polluting and environmentally friendly

can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness,

light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Annealed And Heat Treated

Plate welding heavy work bed, no deformation in 20 years, suitable for ultra-high power 10,000-watt laser. The increase in weight

is very beneficial to the laser cutting machine cutting speed.

Innovative Four Slings Working Bed

For reducing damage to the work bed during laser working, G.WEIKE Innovated the new work bed by adding four slings, and the life

span of the fiber laser cutting machine work bed will be doubled.

All electrical components and laser source are built-in to the independent control cabinet with a dust-proof design to prolong the

lifespan of the electrical components.

Automatic Thermostat

The control cabinet is equipped with air conditioner for automatic constant temperature. This can prevent excessive temperature

damage to components in summer.

In the processing process, each dead corner area can be monitored at any time, the process can be controlled.

It adopts an pneumatic clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-300mm.

It adopts an up and down exchange platform, and the converter is responsible for controlling the exchanging motor. The machine is

able to finish the platform

Laser cutting is highly suitable for innovative applications in sheet metal processing, representing a unique quality. The high production flexibility combined with the great diversity of materials and shapes explain its worldwide recognition as an indispensable technology.

Advantages of Laser Cutting:

High productivity Versatility to cut any shape you need

No tooling costs

High precision with clean edges

CO2 lasers: for cutting all sheet metal thickness up to 20 mm

Fibre lasers: for cutting all sheet up to 50 mm – fast, precise and economical

Minimal heat distortion of parts

15 YEARS PROFESSIONAL FOCUSED ON LASER CUTTING MACHINE

GWEIKE is established in July 2004 , owns more than 500 square meters of researching and office space, more than 32000 square meters factory.All machines passed the European Union CE authentication and are certified to ISO 9001. Products are sold to USA, Canada, Australia, Europe, South east Asia, Africa etc, more than 100 countries and areas, and supply OEM service for more than 30 manufactures.

Additional information

| Laser Type: | Fiber Laser |

|---|---|

| Application: | LASER CUTTING |

| Applicable Material: | metal |

| Condition: | New |

| Cutting Area: | 4000*2000mm |

| Cutting Speed: | 0-120m/min |

| Graphic Format Supported: | AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT |

| Cutting Thickness: | Depends |

| CNC or Not: | yes |

| Cooling Mode: | WATER COOLING |

| Control Software: | Cypcut |

| Place of Origin: | Shandong, China |

| Brand Name: | G.weike laser |

| Certification: | CCC, ce, ISO, Sgs |

| Laser Source Brand: | IPG |

| Laser Head Brand: | Raytools |

| Servo Motor Brand: | Yaskawa |

| Guiderail Brand: | HIWIN |

| Control System Brand: | Cypcut |

| Weight (KG): | 12000 KG |

| Key Selling Points: | Long Service Life |

| Warranty: | 3 years |

| After-sales Service Provided: | Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support |

| After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company |

| Local Service Location: | Egypt, United Kingdom, France, Brazil, Pakistan, Spain, Australia |

| Showroom Location: | Canada, Turkey, United States, Germany, Peru, Saudi Arabia, India, Mexico, Thailand, South Korea |

| Machinery Test Report: | Provided |

| Video outgoing-inspection: | Provided |

| Marketing Type: | New Product 2020 |

| Warranty of core components: | 1 Year |

| Core Components: | Motor, Bearing |

| Electronic component: | Schneider |

| Pneumatic parts: | SMC and Airtac |

| Guide Rail: | Taiwan Brand |

| Water chiller: | Included |

| Voltage: | 380V / 50Hz~60Hz |