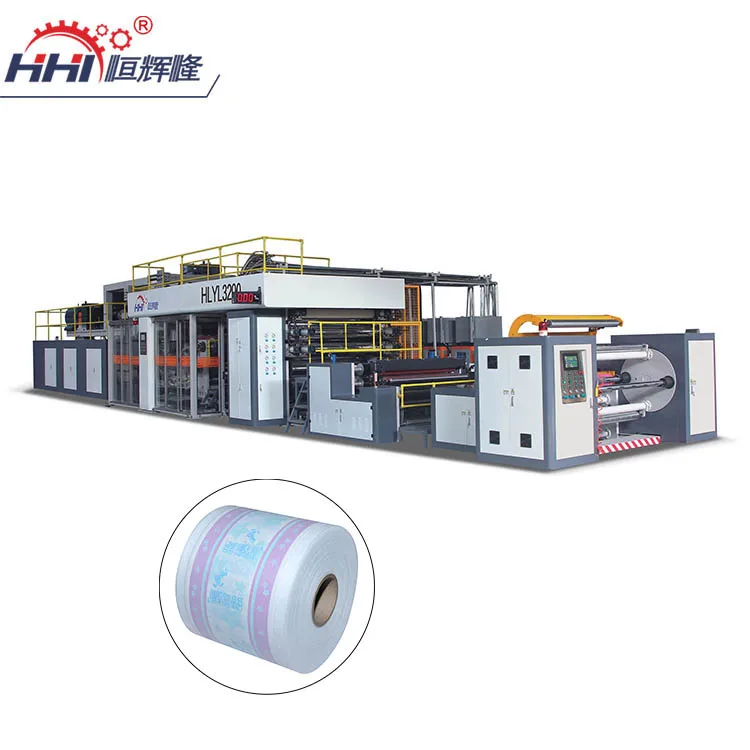

High-Efficiency Pe Film With Nonwoven Paper Coating And Lamination Extrusion Plant Equipment Machine

Description

Wide application range: could be applied to the production of PE cast film, breathable film for hot packs and diapers.

type | HLYL1900B-2900B |

Machine speed | 230m/min |

Production speed | Max150m/min-200m/min |

Basis weight range | (18-60)±2g/m2 |

Product structure | Monolayer |

Extrusion capacity | Min 500kg/h |

Screw diameter | Φ130 |

Product width | 1200mm-2300mm |

Winding diameter | max600mm |

Corona | Online corona treatment(both single-sided and double-sided |

Scrap | Online recycling |

Full Servo Breathable Film Casting Machine Line consists of six units: Extrusion Unit, Casting Unit, Stretching Unit, Embossing Unit, Corona Unit, Winding Unit and Electronic Control Unit. The Embossing Unit can be freely combined according to the customer’s requirements.

Main features:

1. Using independent servo motor for transmission, the Stretching Unit has the feature of stable speed and high-precision function, it can improve product quality effectively.

2. This machine has humanized and intelligent programming, resulting simple and fast operation. The screen could control the temperature of each part of the machine. Besides, the stretching speed is calculated intelligently. With a simple touch on the screen, the production real time data would be achieved efficiently.

3. With stable extrusion on film amount, the weight and thickness of the film could be well controlled.

4. Large speed monitor screen, convenient for operation.

5. The Extrusion Unit adopts hydraulic system for reciprocating motion, therefore it has the feature of stable swing and steady speed, which greatly improves the flatness of the film.

6. With meter-calculator, the alarm alerts while the roll reaches the length pre-set, then overturn and connect material automatically. The function can be completed automatically without staff operation.

7. Safety and humanity: Cast Cooling Unit is provided with safety protection door, and has installed optical fiber detection alarm, it can effectively prevent accidents from mal-operation and protect personal safety of the workers, ensuring the safety of production.

8. Nanjing-Austria technology is introduced to the technological process.

Item | Dot transfer lamination(other used) | Suspension scraping lamination(we used) | ||||

Post-maintenance | Frequently changing the width of the rubber baffle will result in a short life of the rubber baffle. The rubber baffle needs to be replaced frequently. The scraper blade is replaced in about 30 days. The rubber roller is often repaired and replaced, which is troublesome to disassemble. | Since the width of the glue is changed, there is no need to adjust the rubber baffle, and the rubber baffle has a long life. The pressure of squeegee for suspension scraping coating is 2-3KG air pressure relative to the squeegee for dot transfer coating, so the life of the squeegee is relatively long. | ||||

Frequently change the width of the glue coating, the baffle is easy to damage | The rubber roller is easy to be deformed and needs maintenance, and the accuracy must be well controlled. | |||||

Glue coating material | Not suitable for high air permeability and perforated materials, and not suitable for low weight materials, such as (8-15g non-woven fabric, etc.) | Breathable and non-breathable materials, both high and low weight materials are available, and mesh materials can also be coated | ||||

you get all your machines ready, for testing and teaching your technicians how to run the machine.

A5:We generally accept T/T or L/C, and we can negotiate the payment method.

Additional information

| Screw Design: | Single-screw |

|---|---|

| Screw L/D Ratio: | Unapplicable |

| Application: | Film |

| Plastic Processed: | PE |

| Condition: | New |

| Screw diameter (mm): | 130 mm |

| Screw Speed (rpm): | 230 rpm |

| Showroom Location: | None |

| Place of Origin: | Guangdong, China |

| Brand Name: | HHL |

| Warranty: | 1 Year |

| After-sales Service Provided: | Online support |

| Key Selling Points: | High Productivity |

| After Warranty Service: | Video technical support, Online support |

| Local Service Location: | None |

| Applicable Industries: | Manufacturing Plant |

| Marketing Type: | Ordinary Product |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

| Warranty of core components: | 1 Year |

| Core Components: | Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Gearbox, Screw |

| Product width: | 1200mm-2300mm |

| Winding diameter: | max600mm |

| Corona: | online corona treatment(both single-sided and double-sided |

| Scrap: | Online recycling |

| type: | HLYL1900B-3200B |

| Machine speed: | 230m/min |

| Production speed: | max150m/min-200m/min |

| Basis weight range: | (18-60)±2g/m2 |

| Product structure: | Monolayer |

| Output (kg/h): | 500 – 600 kg/h |