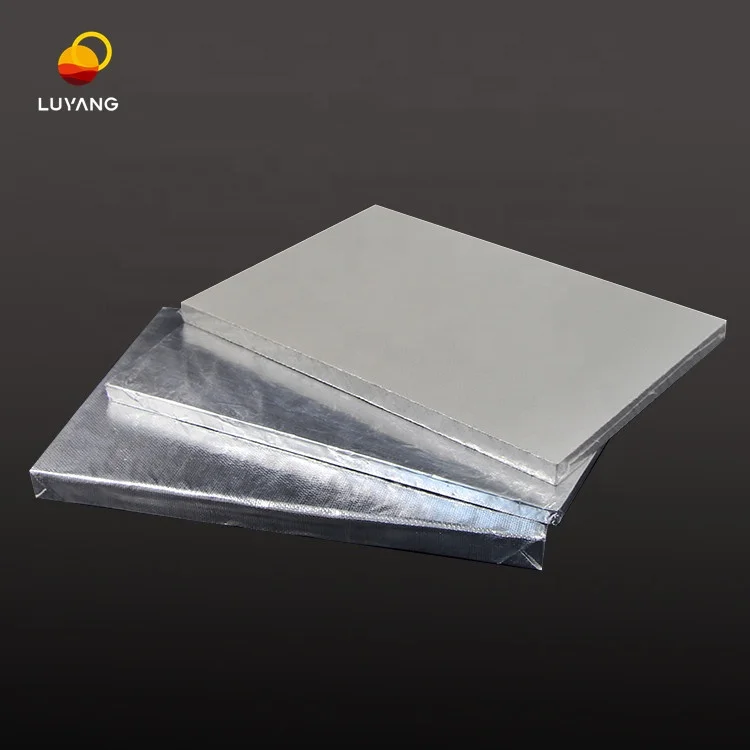

LUYANG Micropore Insulation hard Nano Board With Glass Fiber Cloth

Description

temperature, it has a lower thermal conductivity than still air. The thermal conductivity increases very little with the increase of temperature. At high temperature, its insulation effect is 3-4 times higher than traditional insulation materials. Luyang Microporous Hard Board has high compressive strength, covered with aluminum foil or glass fiber cloth. It is an excellent choice for the lightweight and energy-saving application of kiln.

Description | MICROPOROUS 60H BOARD | MICROPOROUS 90H BOARD | MICROPOROUS 105H BOARD | |||

Recommended Temperature of Use (℃ ) | 600 | 900 | 1050 | |||

Density (kg/m³) | 300/320 | 280/300 | 320 | |||

Modules of Rupture (MPa) | ≥0.15 | ≥0.15 | ≥0.15 | |||

Compressive Strength (MPa, 10% relative deformation) | ≥0.3 | ≥0.3 | ≥0.3 | |||

Permanent Linear Shrinkage (%) | 600℃ x 24h ≤2.0 | 900℃ x 24h ≤2.0 | 1050℃ x 24h ≤2.5 | |||

Thermal Conductivity (W/m·K) | ||||||

100℃ | 0.022 | 0.020 | 0.022 | |||

200℃ | 0.024 | 0.023 | 0.024 | |||

300℃ | 0.028 | 0.026 | 0.031 | |||

400℃ | 0.029 | 0.027 | 0.036 | |||

500℃ | – | 0.033 | 0.040 | |||

600℃ | – | – | 0.048 | |||

Covering Material | Aluminum Foil / PE Foil / Glass Fiber Cloth | |||||

Standard Size (mm) | 600 x 400 x (10-50) | |||||

1000 x 500 x (10-50) | ||||||

Typical Applications

*Back-up insulation in high-temperature furnaces

*Appliances insulation

*Fire protection equipment

*Electronic devices

* Rotary & Shaft Kiln

* Various Incinerator

* Reheating Furnace

* Permanent Lining For EAF Ladle

* General Industrial Furnace etc.

Features

* Thermal conductivity – 2 ~ 10 times lower than the conventional thermal insulation material, 800 degrees only 0.052 w / m k.

* Durability – can be used as a permanent layer of insulation, service life of more than 5 ~ 10 years.

* Safety and environmental protection – pure non-polar material combination, good thermal stability, no release of any harmful substances.

* Economic analysis – the price is lower than 50 % of similar products abroad, 10 ~ 30 % energy saving than conventional materials.

Luyang is a professional inorganic fiber materials manufacturer; drafting unit of international standards and national standards; leaders in energy-saving and environmental protection materials. Luyang has national-recognized enterprise technology center and State Key Laboratory of enterprise. Luyang has 118 patents and 54 scientific and technological achievements.

Luyang has an annual output of 300,000 tons of various ceramic fiber products and 100,000 tons of rock wool products. Luyang has five production bases in Shandong, Inner Mongolia, Xinjiang, Guiyang and Suzhou. Luyang has maintained a leading position in scale, technology, variety and efficiency in domestic industries for many years and ascends among the world’s ceramic fiber industry forefront. Luyang products are in great demand nationwide and sold in more than sixty countries and regions, such as USA, EU, Japan, Vietnam. Luyang products are applied widely in the field of petrochemical refractory insulation, long-distance pipe network insulation, building fire insulation, shipping fire prevention, household appliances fire insulation, high-temperature insulation etc.

1. Strict QC & Fast delivery.2. Free samples are available by freight collect.

3. High quality goods, Perfect Pre-sales, and good designing service.

4. Welcome to visit our factory at anytime on site or online .

5. We will update you the production process after placing order by photos or online.

6. We have special after-sales team to solve your problem during using our products.

2.What kind of product can you offer ?

Our company can offer all kind of refractory insulation materials. For example: Ceramic Fiber Products, Soluble Fiber Products, Alumina Fiber Products, Microporous Board, Insulating Firebricks, Calcium Silicate Products, Mineral Wool, Rock Wool Etc.

3.Can you provide free samples ?

Free samples are available !

4.What is your MOQ?

We don’t have particular MOQ, we can accept any order for any different projects.Price depends on quantity.

5.Can we have a visit to your factory ?

Yes! Of course,welcome to visit our factory at anytime on site or online !

6.What’s the lead time?

Generally it is 7-15 days, or shorter, if the goods are in stock.Or it is 15-30 days, it is according to quantity.

Additional information

| Warranty: | 2 years |

|---|---|

| After-sale Service: | Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Return and Replacement, NONE |

| Project Solution Capability: | graphic design, 3D model design, total solution for projects |

| Application: | Hotel, Villa, Apartment, Office Building, Hospital, School, Mall, Sports Venues, Leisure Facilities, Supermarket, Warehouse, Workshop, Park, Farmhouse, Courtyard |

| Place of Origin: | Shandong, China |

| Brand Name: | LUYANG |

| Model Number: | LYNB |

| Type: | Aluminum Foil / PE Foil / Glass Fiber Cloth |

| Material: | Microporous material |

| Description: | Microporous Hard Board |

| Classification: | 60H/90H/105H BOARD |

| Density(kg/m3): | 280/300/320 |

| Size 1 (mm): | 600x400x(10-50) |

| Size 2 (mm): | 1000x500x(10-50) |

| Maximum Service Temperature,℃: | 600/900/1050 |

| Modules of Rupture (MPa): | ≥0.15 |

| Compressive Strength (MPa): | ≥0.3 |

| Covering Material: | Aluminum Foil / PE Foil / Glass Fiber Cloth |

| Typical Application 1: | Back-up insulation in high-temperature furnaces |