Newest Automatic Drinking Water Bottling Plant/ Equipment Turnkey Project

Description

Full Automatic Water Filling Machine

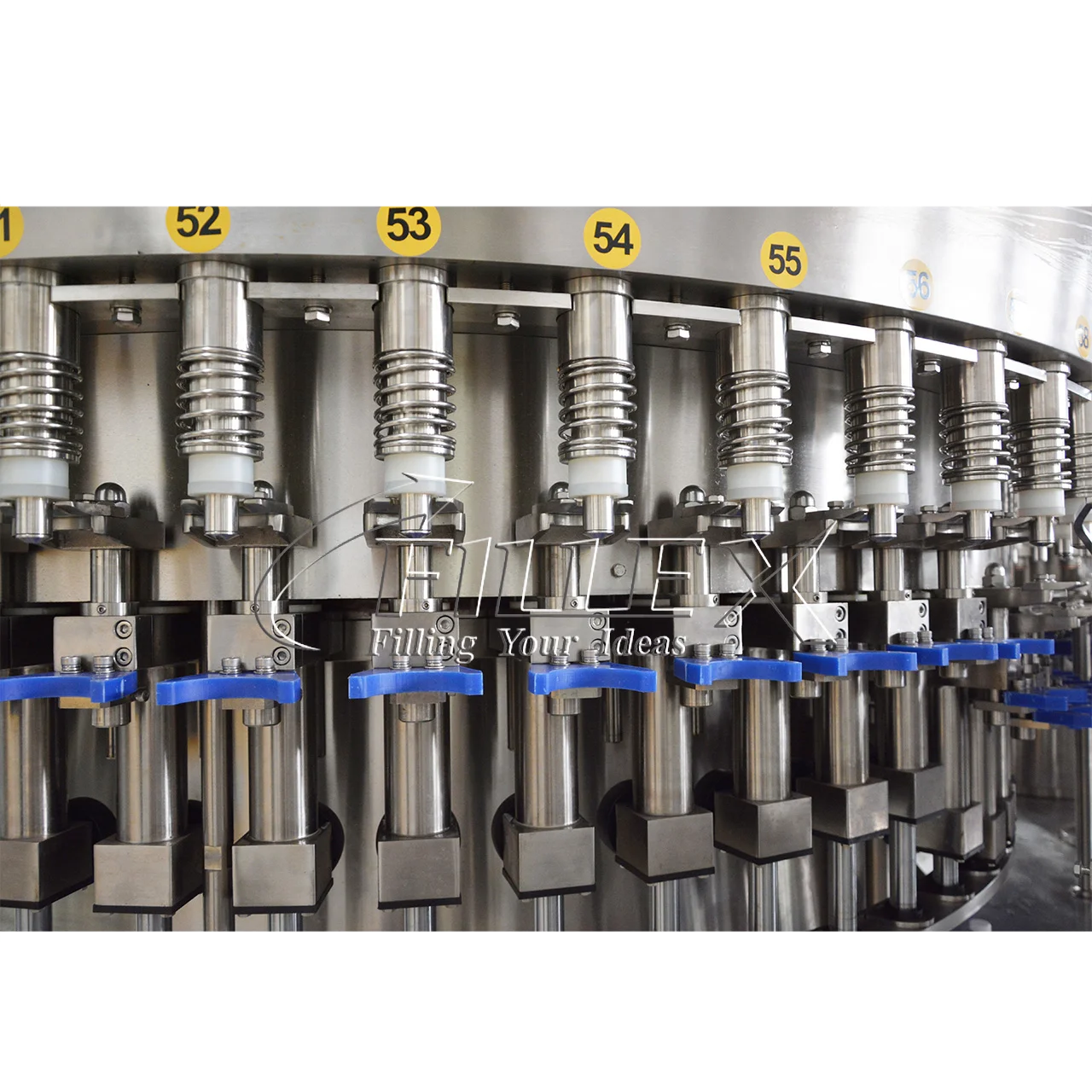

Bottles are transferred to water filling machine through poking bottle star-wheel.The bottle is hold by neck holding

plate after it is in the bottle filling machine. The filling valve ascends and descends by the action of cam. It applies pressure filling method. When filling valve descends and touches bottle jack, it opens and finishes the filling course, when finished, thefilling valve ascends and leaves the bottle while the bottle is transferred into capping machine through transition star-wheelthat clamps bottle neck.

Model (RFC-C) | 14-12-5 | 16-16-5 | 24-24-8 | 32-32-10 | 40-40-10 | 50-50-12 | 60-60-15 |

Capacity(BPH) | 5,000 | 8,000 | 12,000 | 15,000 | 18,000 | 22,000 | 28,000 |

Drive Motor | 2.42 | 3.12 | 3.92 | 3.92 | 5.87 | 7.87 | 11.37 |

Rising Water Pump Power | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 |

Dimension | 2360*1770*2700 | 2760*2060*2700 | 3550*2650*23700 | 4700*3220*2700 | 5900*4150*2700 | 5900*4150*2700 | 5770*5290*2700 |

2 / Optimum uptime: 30 % reduction in changeover and maintenance downtime

3. Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

4 / Hygiene improvement through volume control and contactless filling

<2> Filling volume adjustable in fine rank, same liquid level after filling

<3> All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

<4> 304/316 stainless steel filling pump

<5>Efficient spray nozzle rinse thoroughly and save water for flushing

capping

<2> All 304/316 stainless steel construction

<3> No bottle no capping

<4> Automatic stop when lack of bottle

<5>Capping effect is stable and reliable ,Defective rate ≤0.2%

Main Feature

be operated. Advanced touch screen and PLC control system makes man-machine communication true.

2. Washing part in the bottle water machine is mainly composed of washing pump, bottle clamps, water distributor, up turn-plate,

guide rail, protection cover, spraying device, defrosting tray, rinse water take and rinse water refluxing tank.

3. Filling part in the water filling machine is composed of filling barrel, filling valves (normal temperature and normal pressure

filling), filling pump, bottle hanging device / bottle pedestals, elevating device, liquid indicator, pressure gauge, vacuum pump,

etc.

4. Capping part in this water filling machine is mainly composed of capping heads, cap loader (separated), cap unscrambler, cap

drop rail, pressure regular, cylinder and also we need an air compressor as the auxiliary external equipment.

2. We have the certifications of ISO, CE and so on for our filling machine.

3. Our company filling machine are exported to many countries abroad every year.

4. We can offer free technician support and consultation to help you to order a new filling machin. and start a new company.

5. We can offer one year guarantee for the filling machin you ordered freely.

6. W can send our technician to your country for filling machin commissioning and instruction.

7. Our filling machin. are with good quality and good price.

8. Your inquiry will be replied within 24 hours, you are welcome to contact me in your convenience, please feel free to contact me if any question you have for filling machine.

A:Fillex Machinery Co., Ltd. is a 10-year-old manufacturer specializing in the production of complete beverage filling machinery

and equipment. Such like : Semi-automatic blow molding machine , automatic blow molding machine ,RO water treatment , UF water

treatment ,Pure water filling machine , Juice filling machine , Pulp juice filling machine , Beer filling machine , Oil Filling

Machine , Wine Filling Machine , Can filling machine , Pet bottle filling machine , Glass bottle filling machine , 5 gallon water

filling production line , carbonated soft drink production line ,, three-in-one filling machine, beverage equipment, etc.

bottle unscramber machine,Opp hot glue labeling machine,shrink Label Machine , shrink wrapping machine , carton packaging machine

,UHT ,sterilizer,date printer,etc.

We can help you to build a new beverage factory , can help you design the bottle , design the filling line drawing… Any question

about this filling machine or our factory ,please contact us ,sincerely serve for you .

Q:How can I install my filling machine when the filling machine arrives?

A:We will send the engineers to help you install and test the machines , but the Visa fee, round tickets, accommodation, eating,

and the allowance of 80USD per day per person will be on customer’s side.

Or the customer can send the engineer to our company to complete the inspection of the goods, as well as the installation and

training lessons ,but the Visa fee, round tickets, accommodation, eating, and the allowance will be paid by customers .

Q:What’s your guarantee or the warranty of the quality of the water filling machine ?

A:We offer you high quality filling machine with 1 years guarantee . we will give u free spare parts in 1 years.

If during the warranty period, the quality or specification of the goods is found to be inconsistent with the contractual

requirements, or if the goods are found to be defective (including potential defects or the use of unqualified materials, etc.),

the buyer has the right to use the inspection documents issued by the statutory authority. During the warranty period of the

goods, the buyer shall make a claim against the seller.

Q:Where is your company located ?How can i visit there to check filling machine?

A:Our factory is located in zhangjiagang City,Jiangsu Province,China.

You can fly to Shanghai Pudong International Airport and we are warmly welcome to visit us.(Provide pick-up service.)

Q:How can l get some samples?

A:We have no sample.we will send you more pictures and video about this filling machine,and welcome to visit our factory to see the

machine running in the factory.

Q:How about the quality of your filling machine ?

A:Our company guarantees that the products provided are brand new, unused, with the latest design and suitable materials, and

comply with the quality, specification and performance of the contract in all respects. And all the electric element we all use

the famous brand around the world , such like Schneider ,Mitsubishi etc..

Q:What’s the delivery time of your filling machine ?

A:7-45 days after the T/T deposit or L/C.(The premise is to receive customer’s samples and deposit).

Q:What about Product’s material and configuration use?

A:304 stainless steel, the machine frame material is iron. According to customer requirements, 316 stainless steel is available ,

complete machine stainless steel, and customers demand specified configuration.

prevent dust blown into bottles. – Bottles are held on the neck in the conveyor and transported into filling machine by blowing

power. – All are made of stainless steel SUS 304 /316. – Rack made by high quality carbon steel welded.

remove dissolved solids and bacteria, viruses, etc., desalination rate of more than 99.6 percent, in line with national standards

to produce pure water, the host section contains the security filter, high-pressure pump and reverse osmosis membrane, security

filters for the fourth grade and above pre-treatment systems, high-pressure pump is the host of one of the core equipment for the

reverse osmosis membrane elements to provide sufficient pressure to overcome the penetration resistance to pressure and run to

meet the needs of a device to achieve the rated water.

Bottle Capacity : 200ml-2L / 5L /10L / 3Gallon / 5 Gallon

Machine Capacity : 1000/2000/4000/6000/8000/9000

FL series fully automatic rotary stretch blow molding machine ensures first-class performance which combined with a comprehensive

bottle solution development program to devise the best solution for high speed. The machine features as high-tech component,

stable running, less power and air consumption, minimized maintenance which could meet relevant national food sanitation

requirements and shows the leading status domestically. The machine covers an extremely board range of applications including

still or carbonated water, soft drinks, edible oil, juice and sport drinks, tea and milk or milk drinks.

*Double layer holding furnace ismanufactured to take effect on energy saving

*The steam spray nozzle is divided to be adjustable three segments and the height, position and steam output of every segment can

be adjusted respectively so as to gain the perfect shrinking effect.

*The whole machine is made of 304 stainless steel with heat preservation

*The stainless steel defrosting tray collects condense water.

*The whole machine adopts the water-proof design with the convenience of operation and maintenance

*Double layer holding furnace ismanufactured to take effect on energy saving

*The steam spray nozzle is divided to be adjustable three segments and the height, position and steam output of every segment can

be adjusted respectively so as to gain the perfect shrinking effect.

*The whole machine is made of 304 stainless steel with heat preservation

*The stainless steel defrosting tray collects condense water.

*The whole machine adopts the water-proof design with the convenience of operation and maintenance

packed articles tight and orderliness.This is a fully automatic production line integrated with such processed as automatic

conveying,feeding,tube management,cutting shrinking and cooling shaped-fixing flow.For large collectively counted case (box or

can)packing,it is preferred to encase with PE or PVC Shrinking film before shrink package.

Additional information

| Machinery Capacity: | 4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, Drinking Water Bottling Plant |

|---|---|

| Filling Accuracy: | +-1mm |

| Packaging Material: | plastic, Drinking Water Bottling Plant |

| Filling Material: | Beer, Milk, Water, Oil, Juice, Powder, Drinking Water |

| Type: | Filling Machine |

| Applicable Industries: | Food & Beverage Factory, Food & Beverage Shops, Drinking Water Bottling Plant |

| After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location: | Canada, Turkey, Italy, Viet Nam, Peru, Indonesia, Mexico |

| Showroom Location: | Turkey, Italy, Viet Nam, Peru, Indonesia, Mexico, Thailand, Argentina, UAE, Algeria, Sri Lanka, Bangladesh, Ukraine, Uzbekistan |

| Condition: | New |

| Application: | Beverage, Drinking Water Bottling Plant |

| Packaging Type: | Cartons, CANS, Bottles, Barrel, Bags, Drinking Water Bottling Plant |

| Automatic Grade: | Automatic |

| Driven Type: | Electric |

| Voltage: | 380V |

| Place of Origin: | Jiangsu, China |

| Brand Name: | Fillex Water Filling Machines |

| Dimension(L*W*H): | 2800*2100*2800MM |

| Weight: | 3500KG |

| Certification: | CE ISO for Water Filling Machines |

| After-sales Service Provided: | Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Engineers available to service machinery overseas |

| Warranty: | 1 Year, 1 Year for Water Filling Machines |

| Key Selling Points: | High-accuracy |

| Marketing Type: | New Product 2020 |

| Machinery Test Report: | Provided |

| Video outgoing-inspection: | Provided |

| Warranty of core components: | 1 Year |

| Core Components: | Motor, Pressure vessel, Pump, PLC, Gear, Bearing, Gearbox, Engine, Drinking Water Bottling Plant |

| Product name: | Water Filling Machines |

| Control: | PLC+ Touch Screen |

| Material: | SUS 304 |

| Capacity: | 3000-24000BPH |

| Filling Precision: | ±3mm |

| Function: | Water Filling Machines |

| Bottle type: | PET Plastic Bottle |

| Minimum: | 1 set for Water Filling Machines |