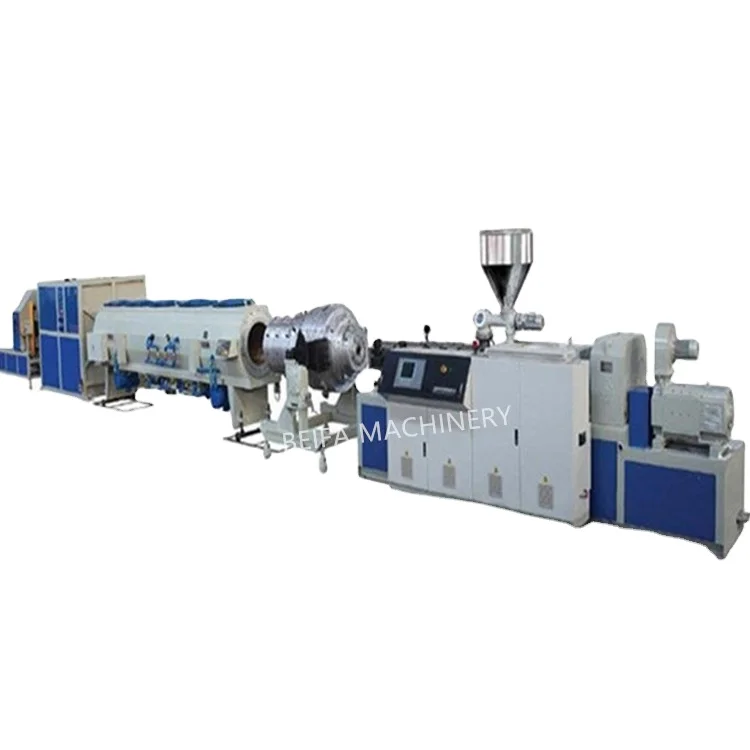

PVC pipe plastic extruder PVC pipe plastic producsion line

Description

China manufacturer upvc pipe machine

Product Detail

| Inverter: | ABB |

| Material: | PVC+additives |

| Motor: | SIEMENS |

| Temperature controller: | OMRON |

| Contactor: | French Schneider |

| Screw and barrel: | 38CrMoAlA |

| Coolingway: | Recycling water |

| Product Keywords | upvc pipe machine |

Features:

1. PVC pipe extrusion line is our main product and have been exported to many different countries. Under our technical supports and formula of material helping, many customers save their cost and take a good occupancy in their local market.

2. PVC pipe extrusion line is mainly used in the manufacture of plastic PVC pipes with various diameters and wall thickness used in the industries such as agricultural and constructional plumbing, cable laying,drain water etc

3. PVC pipe extrusion line is composed of conical twin-screw extruder, vacuum calibration tank, haul-off, cutter and stake etc. The extruder and haul-off adopt imported AC frequency control device, vacuum pump and haul-off motors adopt high-quality products.

Pipe diameter (mm) | 16-40 | 20-63 | 63-200 | 160-315 | 315-630 |

Extruder mould | SJSZ51/105 | SJSZ55/110 | SJSZ65/132 | SJSZ80/156 | SJSZ92/188 |

Extruder power (kw) | 18.5 | 22 | 37 | 55 | 110 |

Max capacity | 120 | 180 | 250 | 350 | 700 |

Detailed Images

The PVC pipe production line includes the below machines:

1. PVC Mixer ( for raw material preparation)

2. Conical Twin Screw Extruder

3. Extrusion Mold

4. Vacuum Tank

5. Cooling Tank ( for large diameter pipes)

6. Haul Off Machine

7. Cutting Machine

8. Stacker

9. Auto Belling Machine ( for pipe connection)

10. Crusher and Milling Machine ( for waste pipe treatment, the recycled PVC could produce pipe again.)

Quality assurance:

1. Vinner is equiped with world advanced computer driving production lines

2. Whole set of pure water processor line featured with RO anti-saturation and advanced testing devices

3. Manufactured in Class 100,000 Cleanroom

About

Zhangjiagang Beifa machinery Co ., Ltd. is a key manufaturer which profesionally produces series plastics machinery.

The enterprise cmpletely absorbs foreign advanced technology and advanced management method to specially provide our customers with the different plastic sheet/board production line;PVC profile extrusion line, the products are well sold all over the country.

PACKAGE:

Standard export carton packing.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Contact

→

Phone: +86 15301567320

Additional information

| Screw Design: | Double-screw |

|---|---|

| Screw L/D Ratio: | 188:1 |

| Application: | PIPE |

| Plastic Processed: | PVC |

| Condition: | New |

| Twin Screw Type: | Counter-rotating conical Twin-screw |

| Screw Material: | 40CrMoTi |

| Screw diameter (mm): | 92 |

| Screw Speed (rpm): | 57 rpm |

| Showroom Location: | Italy, Pakistan, India, Kazakhstan, Tajikistan |

| Place of Origin: | Jiangsu, China |

| Brand Name: | BEIFA |

| Voltage: | 220v/380v/440v/415v |

| Dimension(L*W*H): | 4600*2200*3000 |

| Power (kW): | 110 |

| Weight: | 5600kg |

| Certification: | ISO CE |

| Warranty: | 1 Year |

| After-sales Service Provided: | Field installation, commissioning and training, Engineers available to service machinery overseas |

| Key Selling Points: | Automatic |

| After Warranty Service: | Online support |

| Local Service Location: | Viet Nam, Pakistan, India, Kazakhstan, Tajikistan |

| Applicable Industries: | Manufacturing Plant |

| Marketing Type: | Ordinary Product |

| Video outgoing-inspection: | Provided |

| Machinery Test Report: | Provided |

| Warranty of core components: | 1 Year |

| Core Components: | Motor, PLC |

| Inverter:: | ABB |

| Material:: | PVC+additives |

| Motor:: | SIEMENS |

| Temperature controller:: | OMRON |

| Contactor:: | French Schneider |

| Screw and barrel:: | 38CrMoAlA |

| Coolingway:: | Recycling water |

| PLC: | SIEMENS |

| Output (kg/h): | 50 – 500 kg/h |