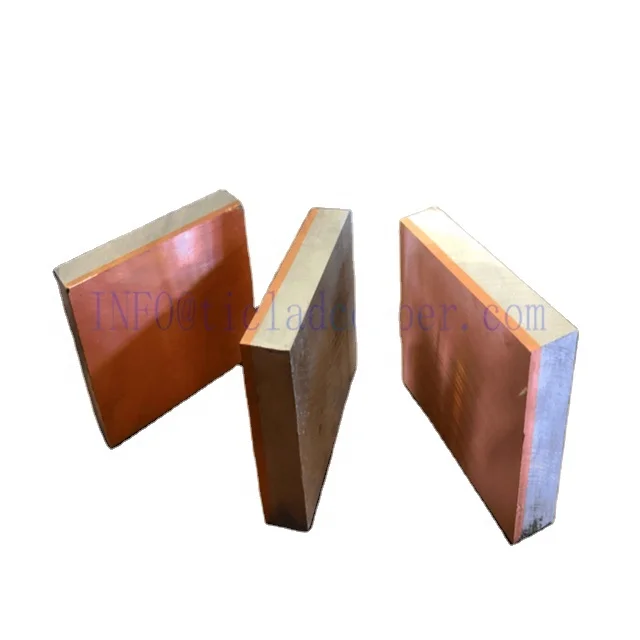

Titanium clad copper plate / titanium cladding sheet/copper titanium clad/

Description

Corrosion-resistant metal composite material manufacturer

Caustic environmental protection equipment expert

Titanium/SS clad copper/Al bar/sheet/wire/tube leading provider

The Explosive welding/explosive cladding is a technology for manufacturing metal-clad materials and a special technique for dissimilar metals welding. It is a combination of mechanics and metal materials science.

The basic principle of explosive cladding:

1, place the cladding plate on the substrate plate, and then put a layer of explosive on the cladding board, and realize the solid metallurgical bonding between the metal layers by using the instantaneous ultra-high pressure and ultra-high speed impact generated when the explosive is exploded.

2, make the cladding plate and the substrate plate high-speed oblique collision through the explosive explosion. The collision peels off and sprays a small amount of metal jet on the contact surface of the material, resulting in a “self-cleaning” effect to expose the solder joint to the non-polluting clean metal. At the same time, the metal body contact surface at the rear of the jet produces solid phase diffusion and fusion welding under the combined action of high pressure, large deformation, high temperature near adiabatic deformation and high temperature compression; the high temperature of the interface after welding It will quickly dissipate heat into the small deformation low temperature substrate, so that the high pressure interface bonding state is quickly quenched and fixed, preventing the metal excessive diffusion reaction and the formation of a large number of brittle phases.

3, The composite interface consists of a direct bond zone, a molten layer and a vortex. This special welding process gives explosive composites two major advantages. First, it can prevent excessive reaction between dissimilar metals, and can weld different kinds of metals that cannot be welded by ordinary fusion welding methods. Second, it is suitable for large-area composite operations and is convenient for manufacturing various cladding materials.

the plate preparation before explosion:

(1) the cladding board: Explosive composite board composite board conventional materials are: titanium-based alloy, nickel-based alloy, Hastelloy, stainless steel, two-way stainless steel, copper, aluminum and other materials. Specifications are customized by the customer’s requirements, most of which require tailor welding. The welding methods are: argon arc welding, plasma welding, arc welding. The industry usually uses argon arc welding. The precautions in the welding process are: the purity of argon is required to be 99.99%, and the welding current depends on the thickness of the composite plate and the material of the composite plate. The positive and negative of the weld during the welding process need to be protected by a protective cover to prevent oxidation of the weld and ensure the quality of the weld.

(2) the Substrate plate: The prepared substrate is firstly removed by a grinding wheel, and then polished with a thousand-page wheel to make the surface smooth and flawless.

(3) Matching board: The soldered laminated board is leveled and polished and placed on a prescribed substrate. For composite panel explosions, the composite panel must be larger than the substrate.

(4) Explosive composite steel plate explosion site

The composite board explosion site requires field work. Ten kilometers away from the residential building, the site requires soft soil and no stone to prevent damage to the board during the explosion.

(5) Explosive composite steel plate explosion welding

According to the specifications of the composite board material to repair the size of the ground (in the industry called the turret) after the turret is repaired, the prepared substrate is leveled to clean the dirt on the composite surface. The gap is laid according to the process, and then the composite is placed over the gap. Spread the explosives, insert the electric detonator, and prepare to explode.

(6)Explosive composite steel plate post-explosion treatment

The explosion-formed composite panel is cleaned, ultrasonically flawed, and the unqualified parts are inspected and repaired. The heat treatment is then carried out. The temperature of the heat treatment depends on the properties of the material.

The composite plate is leveled after heat treatment, and the second test is performed after leveling to prevent cracking during the leveling process. Finally, the qualified composite board is cut and polished. Then the finished product is inspected and the package is shipped after passing the test.

The explosive cladding plates applications:

Application in Civil Field

In the civil field, with the flatness and surface glossiness, copper cladding steel plate is much better than stainless steel plate on mechanical processing performance. With its good heat conductivity, it can substitute for stainless steel since its heat transfer coefficient is 3 times of stainless steel. So it becomes the perfect material for solar water heater, frying-pan, electric rice cooker, etc, such heating and heat transfer devices. Copper-stainless steel clad plate or copper-low-carbon steel clad plate can also make cookware since its good heat conductivity, rigid and nice appearance.

Application in Electronic and Electrical Field

In the fields of electronic and electrical, copper cladding steel plate has been widely used instead of traditional copper and copper alloy to make electronic devices. Armor cable used to be made of copper or copper alloy, however, copper-stainless steel clad metals take the place of copper or copper alloy now, not only ensuring the electric conductivity, and corrosion resistance, but also increasing strength, and reducing thickness.

Application In Machinery Manufacturing

In the field of machinery manufacture, copper cladding steel plate can make heat exchangers, synchronizer cone rings, reducer worm gears, bearing bushes, etc. Copper-steel and aluminum-steel clad metals can make bimetal or multi-metal bearings, bearing bushes, and liner tubes.

Application In Transportation

In the field of transportation, copper cladding steel plate can be used for linear motor’s clad induction plate (copper-steel clad induction plate) on light rail locomotive and subway train. This material not only has good electrical conductivity and good in corrosion resistance, but also improves the strength, and reduces the thickness as well as the cost.

Application In Nuclear Power Projects

In the field of nuclear power projects, copper-stainless or copper-nickel alloy, copper-low carbon steel clad metals can make nuclear storage containers. Big copper cladding steel plate can make linear accelerator cavity for high energy physics research.

Application in Marine Engineering Field

In the marine engineering field, copper cladding steel plate and copper-titanium clad plate can make offshore oil platform structure which can meet properties of high strength, seawater corrosion resistance.

Application In Shipbuilding Industry

In the shipbuilding industry, copper cladding steel plate can weld ship parts or warship parts which ensure high strength, seawater corrosion resistance.

Application In Metallurgical

In the metallurgical industry, copper cladding steel plate is used for electroplating, electrolysis electrode, processing electrode for discharge, grounding rod, current conducting arm body, electrode clamp, and an electrode clamping-release device and so on. Copper-steel or aluminum-steel clad metal can be used for bimetal bearing, bearing bush, and liner tube, wear-resistant plate, self-lubricating slide plate, etc.. Copper-steel clad plate can make electrometallurgical furnace and bi-layer water cooling shell & bi-layer crystallizer of melting furnace.

Application In Military Field

In the military field, copper cladding steel plate can make transmitter, not only solves the leakages, joint corrosion such problems, but also simplifies the manufacturing process, and reduces the cost. If making shells with copper-steel-copper clad metals substituting for brass, it will be much cheaper and much better of ballistic performance.

The clad plates/metals we supply:

Stainless steel clad plates;

Duplex steel clad plates;

Titanium steel clad plates;

Titanium and copper clad plates;

Nickel steel clad plates;

Zirconium steel clad plates;

Copper and steel clad plates;

Copper and Aluminum clad plates;

Aluminum and steel clad plates;

5-layered Steel/Titanium/Nickel/Aluminum clad plates.

Two-layered Clad Plate | ||||

Product | Materials | Specification () | Production Code | Application |

Ti/Steel Clad | Gr.1,Gr.2,Gr.7, | (1.5~12+2~200)*<4110*6000 | ASTM B898 | Petro-chemical, Vacuum Salt Industry, Chlor-alkali, Metallurgical etc. |

Ti/Stainless Steel Clad | Gr.1,Gr.2,Gr.7, Gr.12/304L,316L ,410S etc. | (1.5~12+2~120)*<4110*6000 | ASTM B898 | Petro-chemical,Chlor-alkali, Space, Food, Light Industry, Medicine etc. |

Ti/Al Clad | Gr.1,Gr.2,Gr.7, Gr.12/2117,5052 etc. | (1.5~12+2~50)*<1500*4000 | Negotiable | Aerospace, Kitchenware, Chemical Industry, Ship,etc. |

Ti/Cu Clad | Gr.1,Gr.2,Gr.7, Gr.12/C11000,C10200 etc. | (1.5~12+2~100)*<2000*4000 | Negotiable | Power Industry, Electrolysis Industry, Hydrometallurgy etc. |

Ti/Ni Clad | Gr.1,Gr.2,Gr.7, Gr.12/N02201,N02200 | (1.5~12+2~50)*<2000*4000 | ASTM B898 | Metallurgical Industry etc. |

Ni/Steel Clad | N02201,N0220,B-3,C-22,Monel/Gr.60(N),Gr.70(N) | (2~20+12~100)*<2000*<5000 | ASTM SA-265 | Chlor-alkali, Petro-chemical, Pulping, etc. |

Elegant group titanium and titanium alloy clad composites is the leader in the titanium industry. If you know the type clad composites you are interested in, you are kind to select it. When you are not sure which one you need, or would like to know more information, feel free to call us directly to discuss your particular requirement and we can help you decide which one is the best one.

Email: info at ticladcopper.com 47165648 at qq.com

Skype: amazonzhang158888

Whatsapp/we chat/Mobile: 0086-18892227363

1. plastic films inside;

2. carton boxes or wooden cases outside;

3. according to youre requirements

1, We could produce titanium clad copper plate/bar, stainless steel clad copper plate/bar, copper clad steel plate/bar, copper clad steel plate/bar, nickle clad copper plate/bar, Zr clad copper bar /rod/ pipe/tube/wire/plate/sheet

2, the shape, the size, the material according to customer demand

3, No MOQ

4, 24 -7 service

1, why do you choose our company?

we have more than 20 years producing the metal clad composite to more than 30 countries. our clad bars/plates are used by

metal bonding or explosion bonding technology, which make the two or three kinds of metal best connection together

2, could you provide the weld or CNC cut service?

yes, we could weld , drill , cut, bend according to your detailed demand.

Additional information

| Place of Origin: | Shanxi, China |

|---|---|

| Brand Name: | elegant |

| Application: | wet metallurgy, electrolysis, |

| Technique: | metal / explosion bonding |

| Grade: | GR1 TI, GR2 TI, COPPER |

| Powder Or Not: | Not Powder |

| Ti Content (%): | 99.6% |

| Shape: | round |

| Certificate: | ISO9001:2015 |