Vente!

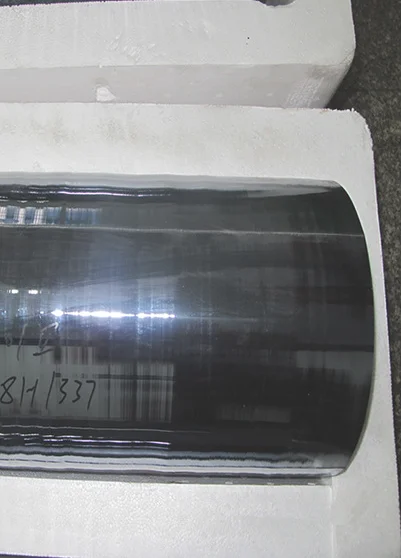

8 Inch IC Grade Or Semi Silicon Wafer Costormised Semi of IC grade mono silicon ingot

La description

Présentation du produit

Processing customization service

Purity99.99999999%

MCZCraft

Senshuo technology silicon Rod customization process

Production process

Charging furnace

Polysilicon material and impurities are put into a quartz crucible, and the type of impurities depends on the N or Ptype of resistance.

Charging process

The furnace is closed and pumped into high purity Argon to maintain a certain pressure range. The graphite heater power supply is turned on and the polysilicon material is melted by heating 1420°。

Necking growth

After the temperature of the silicon melt stabilized, the seed crystal was immersed into the silicon melt slowly. Because of the thermal stress of the seed crystal in contact with the silicon melt field, dislocation would occur in the seed crystal.

Free-standing growth

After growing the thin neck, la

temperature and the pulling speed are lowered, so that the crystal gradually increases to the required size.

Equal diameter growth

After the neck and shoulder are long, the diameter of the Rod can be kept positive or negative 3MM by adjusting the speed and temperature.

Final Cooling

The diameter of the crystal rod is gradually reduced until it becomes a cusp to separate from the liquid level. The process is called tail growth.

CZ and FZ

Almost 90% of the silicon used in the semiconductor industry is grown by czochralski method。

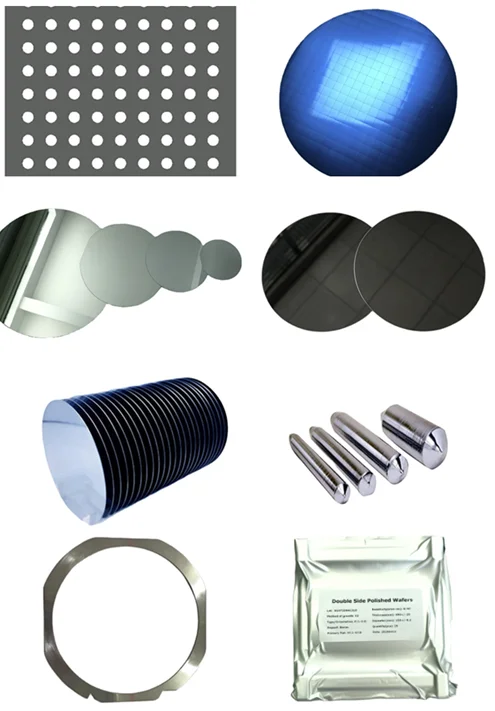

Détails du produit

Wafer manufacturing in the semiconductor field, the technology content is quite high, the technical process requirements are very high

Certificate of competency

In strict accordance with the monocrystalline silicon production process, factory to provide certification.

Drawing process

Increasing minority carrier life, decreasing oxygen content,

continuously increasing production capacity.

Machine Polishing

Machine de soufflage de bouteilles en PET semi-automatique Machine de fabrication de bouteilles Machine de moulage de bouteilles

La machine de fabrication de bouteilles en PET convient à la production de récipients et de bouteilles en plastique PET de toutes formes.

La machine de fabrication de bouteilles en PET convient à la production de récipients et de bouteilles en plastique PET de toutes formes.

Certificat

Logistics Capability

Présentation de l'entreprise

Dongguan Senshuo Technology Co., Ltd. a été établi en 2010. It is a professional semiconductor material solution provider. It is committed to providing customers with comprehensive silicon wafer solutions, ranging from Dummy Wafer to test level. Silicon wafers (Test Wafer), silicon for discrete devices, silicon for integrated circuits, grinding silicon for special diodes and energy-saving lamp electronic rectifiers, silicon wafers for filter coating, etc. At the same time, we can also customize products according to customers’ special requirements. The size covers 4 inches to 12 inches, and can provide single-sided/double-sided polishing, thinning, cutting, MEMS and other processing services of semiconductor silicon wafers.

FAQ

Q: What is your main product?

UN: Single Crystal Silicon Wafer with infrared Si substrate,double-sided polishing filter.

Q: Combien de temps dure votre délai de livraison?

UN: Il faut généralement 7-15 jours de travail.

Q: Fournissez-vous des échantillons?

UN: We can provide samples of conventional virtual wafers, but the minimum order quantity for custom wafers is 25 pièces

UN: Single Crystal Silicon Wafer with infrared Si substrate,double-sided polishing filter.

Q: Combien de temps dure votre délai de livraison?

UN: Il faut généralement 7-15 jours de travail.

Q: Fournissez-vous des échantillons?

UN: We can provide samples of conventional virtual wafers, but the minimum order quantity for custom wafers is 25 pièces

Informations Complémentaires

| Noter: | 9N (99.9999999%) |

|---|---|

| Dimensions: | 8 inches |

| Alloy Or Not: | Non-Alloy |

| Secondary Or Not: | Non-secondary |

| Lieu d'origine: | Guangdong, Chine |

| Marque: | Senshuo technologies |

| Numéro de modèle: | N/P |

| Nom: | Lingots de silicium |

| Taille: | 8 inches |

| Growth Method: | CZ/FZ |

| Purity: | 99% |

| Emballer: | Packed |

| MOQ: | 10kg |